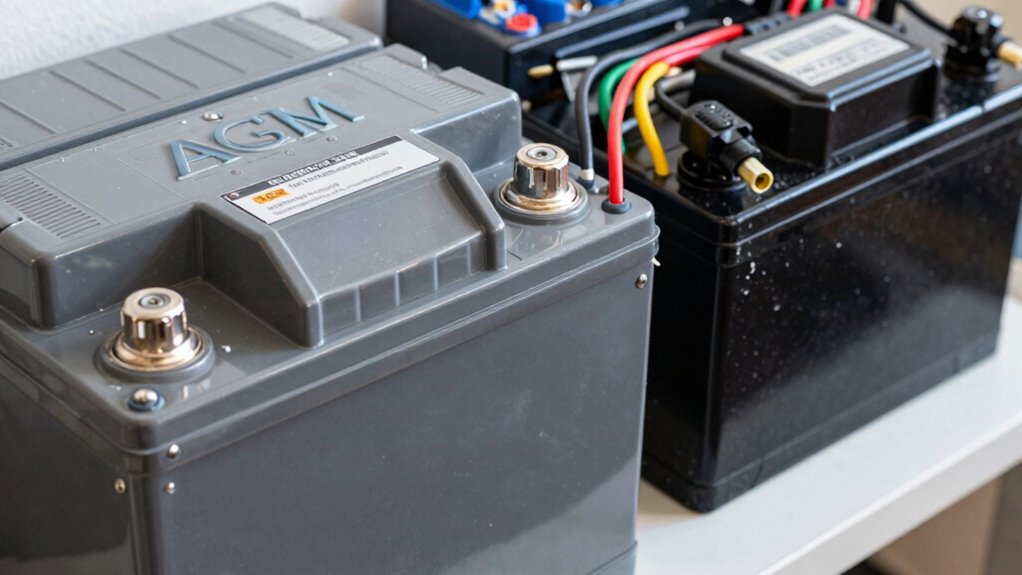

Switching from AGM to lithium batteries means you’ll need to update your charging method and wiring. Lithium batteries require higher voltage settings (~14.6V) and faster charging profiles, so you’ll need chargers designed for lithium chemistry with proper voltage regulation and a built-in BMS. Additionally, upgrade your wiring gauge and protection devices to handle higher currents safely. For more detailed tips on ensuring safe and efficient setup, keep exploring how these changes work together for your system.

Key Takeaways

- Lithium batteries require higher charging voltages (~14.6V) and faster charging profiles compared to AGM batteries.

- Upgrading wiring gauge and protection devices is essential for handling higher currents in lithium systems.

- Use chargers compatible with lithium chemistry, featuring proper voltage regulation and BMS integration.

- Proper wiring and fuse sizing are critical to prevent overheating, overcurrent, and ensure system safety with lithium batteries.

- Switching to lithium often necessitates system adjustments, safety protocols, and regular maintenance for optimal performance.

How Do AGM and Lithium Batteries Differ in Charging Needs?

While both AGM and lithium batteries store energy for your vehicle or device, they have different charging requirements that can impact their performance and lifespan. AGM batteries typically have a lower charging voltage, so you need to guarantee your charger matches their voltage compatibility to avoid damage. Lithium batteries, on the other hand, require a higher charging voltage to reach full capacity safely. Their battery capacity also influences charging speed; lithium batteries usually charge faster and can handle more rapid cycles. Proper charging is essential to maximize lifespan and efficiency. Using the wrong charger or ignoring voltage compatibility can cause overheating or reduced capacity. Battery chemistry plays a critical role in determining the specific charging protocols needed for each type. Additionally, understanding the charging profiles ensures that each battery type receives the appropriate current and voltage throughout the charging process, preventing potential damage. Being aware of thermal management is also crucial, as temperature variations significantly affect charging performance and safety. Properly managing thermal conditions during charging can extend battery life and improve safety.

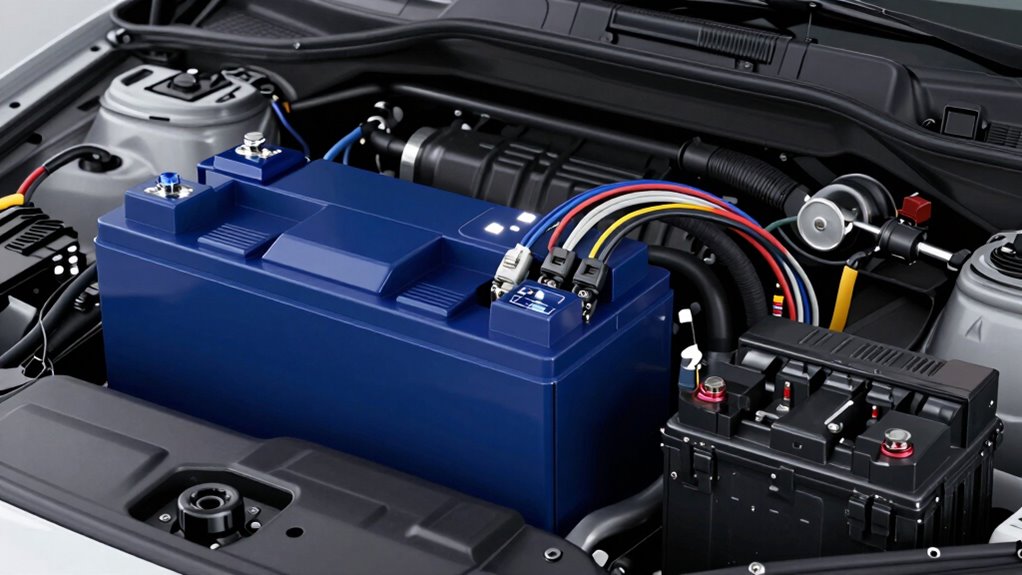

What Wiring Changes Are Needed When Switching to Lithium Batteries?

Switching to lithium batteries often means adjusting your wiring setup to accommodate their different electrical characteristics. To guarantee safety and performance, consider these changes:

Switching to lithium batteries requires wiring adjustments for safety and optimal performance.

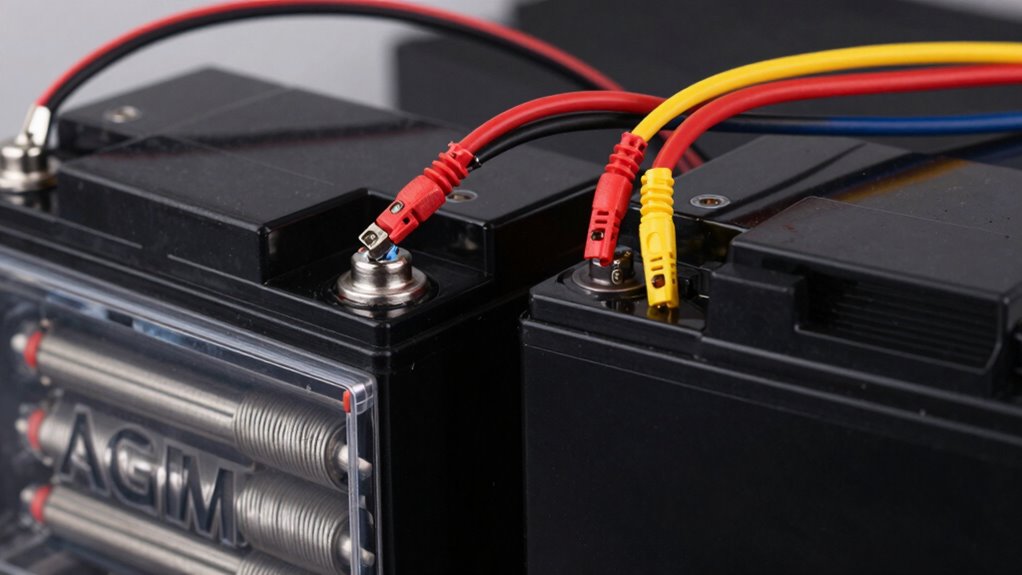

- Upgrade your cable gauge to handle higher current loads without overheating or voltage drops.

- Install appropriate circuit protection to prevent overcurrent or short circuits, which are more critical with lithium’s fast charging capabilities.

- Use heavy-duty fuses or circuit breakers rated for lithium systems to avoid damage.

- Check all wiring connections for tightness, reducing resistance and ensuring reliable power flow.

- Proper cable management is essential to prevent potential hazards and ensure the longevity of your lithium batteries. Ensuring proper battery wiring can also help optimize charging efficiency and extend battery life. Additionally, wiring configuration can influence the overall safety and system performance.

These modifications help manage the increased current and protect your system, making the switch to lithium safer and more efficient. Proper wiring and circuit protection are essential for peak performance and longevity of your lithium batteries.

How to Set Up Your Charging System for Lithium Batteries

Setting up your charging system for lithium batteries requires a few key adjustments to guarantee safety and efficiency. First, implement proper battery management systems (BMS) to monitor voltage and prevent overcharging or deep discharging. This ensures your lithium batteries stay within safe voltage limits. Next, adjust your voltage regulation settings on your charger to match lithium-specific charging profiles, typically around 14.6V for full charge. Using a charger compatible with lithium chemistry is essential. Additionally, verify that your wiring can handle higher current flows safely. Regularly check connections and ensure the charger’s settings are correctly configured for lithium batteries. Proper wiring safety is crucial when working with higher current capacities. To further enhance charging safety, consider installing fuse or circuit breaker protections. Ensuring proper connection integrity can prevent potential hazards and improve overall system reliability. Incorporating battery temperature monitoring can also help optimize charging cycles and extend battery life. Implementing proper charging protocols ensures your batteries are maintained correctly and safely, ultimately extending their lifespan. These steps help protect your investment, improve battery longevity, and optimize your system’s performance.

Common Wiring and Charging Mistakes With Lithium and AGM Batteries

Understanding common wiring and charging mistakes is crucial to prevent damage and guarantee safety when working with lithium and AGM batteries. Mistakes can compromise Battery Management and lead to voltage compatibility issues. Here are four common errors to avoid:

- Ignoring proper fuse sizing, risking overloads and damage.

- Connecting batteries in parallel without balancing, causing uneven Voltage Compatibility.

- Using incorrect wiring gauges, which hampers efficient current flow.

- Overlooking the importance of a dedicated Battery Management System (BMS) for lithium batteries, risking overcharge or deep discharge.

- Neglecting proper regional safety standards and safety considerations can also lead to missteps in battery setup and use. Additionally, understanding how water-related safety principles apply in battery installation can help prevent hazards in certain environments. Being aware of maintenance best practices helps ensure long-term battery health and performance. Proper piercing hygiene and avoiding infection risks are essential for safe and effective piercing procedures.

Top Tips for Safe and Efficient Battery Wiring and Charging

To guarantee safe and efficient battery wiring and charging, focus on proper planning and adherence to best practices. Start by ensuring correct wiring connections, using appropriate gauge cables, and securing terminals tightly. Proper wiring prevents shorts and ensures efficiency. Regular battery maintenance, like checking for corrosion and cleaning terminals, prolongs lifespan. Additionally, understanding the importance of battery lifespan can help you extend the usability of your batteries. Using the correct wiring techniques is crucial for safety and performance. Voltage regulation is vital; use a quality charger with built-in regulation to prevent overcharging. It’s also beneficial to familiarize yourself with proper safety procedures to avoid accidents during installation. Incorporating Indonesian decor masks and Balinese elements into your space can inspire a harmonious environment that emphasizes both aesthetics and cultural appreciation. To understand key principles, consider this table:

| Keep in Mind | Why It Matters |

|---|---|

| Proper wiring | Prevents shorts and ensures efficiency |

| Voltage regulation | Avoids damage and maximizes lifespan |

| Battery maintenance | Maintains performance and safety |

Following these tips helps you optimize performance, extend battery life, and maintain safety during charging and wiring. Additionally, understanding the importance of affiliate disclosure and privacy policies can help you make informed decisions when purchasing or researching equipment online.

Frequently Asked Questions

How Do Temperature Factors Affect AGM and Lithium Battery Performance?

Temperature factors importantly impact both AGM and lithium batteries. You need to contemplate thermal management to prevent overheating or extreme cold, which can reduce efficiency. In hot conditions, batteries may experience decreased voltage stability, leading to shortened lifespan. Cold temperatures slow chemical reactions, causing performance drops. Proper thermal management helps maintain consistent voltage stability and overall performance, ensuring your batteries operate reliably across varying temperatures.

Can I Mix AGM and Lithium Batteries in the Same System?

Mixing AGM and lithium batteries is like blending fire and ice—you risk damaging both. You can’t simply connect them in the same system because of differing battery compatibility and charging protocols. Each type requires specific charging voltages and current settings. To keep your system safe and efficient, stick to one battery type or use a battery management system designed to handle both, ensuring they work together harmoniously rather than fighting each other.

What Are the Maintenance Differences Between AGM and Lithium Batteries?

You’ll find that lithium batteries generally need less maintenance than AGM batteries, which require regular checks on water levels and terminal cleanliness. Lithium batteries have a longer lifespan and lower maintenance costs, so you won’t need to replace them as often. With AGMs, you’ll spend more time on upkeep and monitoring, but lithiums offer a more hassle-free, longer-lasting solution that saves you money over time.

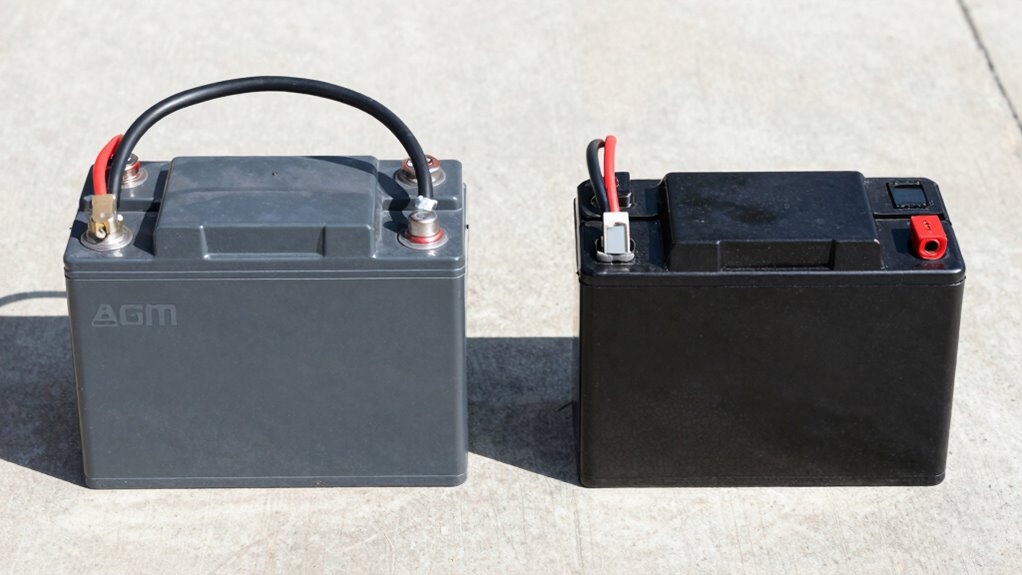

How Do Weight and Size Compare Between AGM and Lithium Options?

You’ll find that lithium batteries are considerably lighter and more compact than AGM options, making them easier to install and freeing up space. While both have similar battery capacities, lithium batteries often offer a longer lifespan, which enhances their overall value. This weight and size difference means you can upgrade to a smaller, lighter battery without sacrificing capacity, and enjoy a better lifespan comparison for your needs.

Are There Specific Inverter Requirements for Lithium Batteries?

Did you know lithium batteries require specific inverter compatibility? You need inverters that support charging protocols designed for lithium chemistry, ensuring safe and efficient charging. Many inverters now come with built-in lithium support, but double-check to avoid damage or reduced lifespan. Using the right inverter helps you maximize performance and safety, so always verify inverter specifications for lithium batteries before installation.

Conclusion

Switching from AGM to lithium batteries is like upgrading your toolbox—you need the right tools and know-how. By understanding their charging needs, making proper wiring changes, and following safety tips, you’ll keep your system running smoothly and safely. Think of it as fine-tuning a musical instrument—you want everything in harmony. With the right setup, you’ll enjoy reliable power and peace of mind, turning your battery system into a well-oiled machine ready for any adventure.