To keep your outboard engine running smoothly, follow a regular maintenance schedule. Change the oil every 50 hours or seasonally, inspect and replace spark plugs annually, and flush the cooling system before and after heavy use. Check and grease the propeller and gearcase regularly, and inspect the fuel system before each trip. By staying proactive with these tasks, you’ll guarantee ideal performance and longevity. Continue exploring to learn detailed timing and tips for each step.

Key Takeaways

- Perform a thorough pre-season inspection, including cooling systems, fuel lines, and electrical connections.

- Change engine oil and replace filters every 50 hours of use or annually.

- Inspect and clean the propeller, gearcase, and lubricate moving parts regularly.

- Check and replace fuel filters, drain old fuel, and stabilize fuel before storage.

- Schedule proactive parts replacement such as spark plugs, water pumps, and hoses based on manufacturer guidelines.

Top picks for "outboard maintenance schedule"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

Why Regular Outboard Maintenance Keeps Your Motor Running Smoothly

Regular outboard maintenance is essential because it guarantees your motor runs smoothly and reliably. When you keep up with routine checks, you improve fuel efficiency, saving you money and extending your boat’s range. Well-maintained components ensure the engine burns fuel more effectively, reducing waste and emissions. Additionally, regular maintenance helps prevent corrosion, especially in saltwater environments. By inspecting and cleaning parts regularly, you stop salt and moisture from causing rust and deterioration. This not only prolongs the life of your outboard but also keeps it performing at its best. Staying proactive with your outboard care ensures it runs smoothly, efficiently, and stays protected against damaging elements. Performing regular preventive maintenance can also identify potential issues early, avoiding costly repairs down the line. Incorporating corrosion protection techniques into your routine can further safeguard your engine from harsh conditions. Regularly applying protective coatings adds an extra layer of defense against corrosive elements, especially in challenging environments. Additionally, using quality lubricants helps reduce friction and wear on moving parts, extending the lifespan of your engine. Moreover, understanding the seasonal maintenance needs can help you prepare your outboard for different weather conditions and usage cycles.

How Often Should You Change the Outboard Oil?

Knowing when to change your outboard oil is key to keeping it running smoothly. You should follow the recommended oil change interval and watch for signs of oil degradation, like increased smoke or engine noise. Choosing the right oil guarantees peak performance and protection for your motor. Regularly inspecting the oil for proper maintenance can help you identify potential issues early and ensure your outboard remains in optimal condition. Additionally, using the right oil and adhering to safety tips can make routine maintenance safer and more effective. Proper oil selection and timely changes are essential for extending the life of your engine and maintaining optimal performance. Being aware of urban traffic confidence and gear care tips can further support your overall boating experience. To keep your engine in top shape, consider inspecting oil filters regularly and replacing them as recommended.

Recommended Oil Change Interval

Changing your outboard oil at the right intervals is essential to keep your engine running smoothly and prevent costly damage. Typically, you should change the oil every 50 hours of use or at least once a season, whichever comes first. If you frequently operate in harsh conditions, such as saltwater or dusty environments, consider more frequent changes. Proper maintenance of your boat trailer and marine electronics also supports engine longevity, ensuring everything functions cohesively. Regular oil changes help remove contaminants and prevent engine wear. By sticking to these intervals, you’ll maximize performance, reduce repairs, and keep your boat ready for the water whenever you are. Free Floating is an important concept for understanding how to optimize your maintenance routine and keep your boat in top condition. Additionally, paying attention to engine diagnostics can help identify issues early before they lead to significant damage. Regularly inspecting and maintaining your oil filters can further enhance engine protection and efficiency. Moreover, understanding the contributing factors that affect oil degradation can help you tailor your maintenance schedule more effectively. Incorporating oil analysis into your routine can also provide valuable insights into the engine’s health and help determine optimal oil change intervals.

Signs of Oil Degradation

Oil degradation can happen more quickly than you might expect, especially if you notice certain signs that indicate it’s time for a change. Look for dark, sludgy oil that’s thick or gritty, which signals breakdown. Unusual engine noises or rough idling can also point to oil that’s lost its lubricating qualities. Additionally, contaminated oil can compromise corrosion prevention, risking damage to internal components and the fuel system. Regularly checking your oil’s condition helps you catch these issues early. Keep an eye out for:

- Increased engine wear or corrosion signs

- Reduced lubrication efficiency

- Presence of water or debris in the oil

- Proper maintenance practices can help ensure your engine remains in good condition. Ensuring proper oil circulation can also prevent localized heat buildup that accelerates degradation. Addressing these signs promptly helps maintain ideal performance and prolongs your outboard’s lifespan. Remember, timely oil changes support corrosion prevention and fuel system health.

Proper Oil Selection

Monitoring the condition of your outboard’s oil is vital to determining how often to change it. Proper oil selection guarantees your engine runs smoothly and lasts longer. When choosing oil, consider oil compatibility—using the right type prevents damage. Decide between synthetic and mineral oils based on your boat’s needs. Synthetic oils generally offer better stability, temperature tolerance, and longer intervals between changes, making them ideal for frequent use or tougher conditions. Mineral oils are more affordable and suitable for casual boating. Always check your manufacturer’s recommendations for oil type and change intervals. Regularly inspecting oil quality helps you catch degradation early, but choosing the right oil from the start is essential to maintaining ideal engine performance and avoiding unnecessary maintenance. Proper gear care can also extend the life of your outboard by preventing contamination and ensuring optimal operation. Additionally, understanding oil degradation signs can help you determine when a change is truly needed, optimizing your maintenance schedule. Being aware of oil testing techniques can further assist in assessing oil condition and timing your oil changes more accurately. Incorporating oil analysis methods into your routine can provide detailed insights into oil health and prolong engine longevity.

When to Inspect and Replace Your Spark Plugs

Regularly inspecting your spark plugs is essential to keep your outboard running smoothly. You should check them during routine maintenance or if you notice engine misfires, poor acceleration, or difficulty starting. Look for signs like fouling, corrosion, or worn electrodes, which indicate it’s time for spark plug replacement. Proper inspection also involves an ignition system check to ensure sparks are strong and consistent. Consider these key points:

- Replace spark plugs if electrodes are worn or damaged

- Clean or gap plugs to manufacturer specifications

- Conduct an ignition system check to verify proper firing

How Frequently Should You Flush and Check Your Cooling System?

To keep your outboard’s cooling system functioning properly, you should flush and check it at least once every season or after extended use in harsh conditions. Regular flushing removes salt, debris, and corrosive build-up that can damage components. When checking, confirm coolant levels are adequate and the antifreeze mixture is properly balanced. Low coolant levels can cause overheating, so top it off if needed, using the recommended antifreeze mixture for your engine. Inspect hoses and fittings for leaks or cracks, replacing any damaged parts. Proper maintenance helps prevent engine overheating and extends the lifespan of your cooling system. Don’t forget to follow your manufacturer’s guidelines on coolant types and intervals for ideal performance.

How to Maintain the Propeller and Gearcase for Peak Performance

Maintaining your outboard’s propeller and gearcase is vital for ideal performance and longevity. Regular propeller inspection helps identify bends, cracks, or damage that can cause vibration or reduced speed. When inspecting, check for fishing line or debris wrapped around the shaft. Gearcase lubrication is essential; verify the gearcase fluid is clean and at the proper level to prevent corrosion and gear wear. Proper maintenance includes:

- Removing and inspecting the propeller for damage, then greasing the shaft before reinstallation

- Draining old gearcase lubricant and refilling with the manufacturer-recommended gear oil

- Checking for water intrusion or metal shavings in the gearcase

Consistent attention to these tasks keeps your outboard running smoothly and extends its lifespan.

When and How to Keep Your Outboard Battery Charged and Clean

Ensuring your outboard battery stays charged and clean is key to reliable starts and smooth operation on the water. Regular battery maintenance involves checking the voltage and ensuring connections are tight and corrosion-free. To keep it charged, use a trickle charger if the boat will be unused for extended periods, preventing deep discharges. When performing cleaning procedures, disconnect the battery first. Use a mixture of baking soda and water to scrub away corrosion on terminals and cables, then rinse with water and dry thoroughly. Maintain a clean battery terminal environment to prevent electrical issues. Proper battery maintenance not only extends the life of your battery but also ensures your outboard starts reliably every time you hit the water.

How to Prepare Your Outboard for Winter and Summer Seasons

Preparing your outboard for seasonal changes is essential to keep it running smoothly year-round. You’ll want to drain and flush the system, change the gear oil, and inspect the components carefully. Covering your outboard afterward safeguards it from the elements and ensures it’s ready for the next season.

Drain and Flush System

Before storing your outboard for winter or summer, draining and flushing the system is essential to prevent corrosion and buildup. Start by disconnecting the marine battery to avoid electrical issues. Then, drain old fuel from the fuel filters and lines to prevent gum formation. Next, flush the cooling system with fresh water to remove salt, dirt, and debris. You can do this by running fresh water through the intake while the engine is in a safe, upright position.

- Remove and clean fuel filters regularly to guarantee efficient operation

- Use fresh water to flush the cooling system thoroughly

- Check the marine battery for corrosion and proper charge status

Performing these steps guarantees your outboard is clean, protected, and ready for the next season.

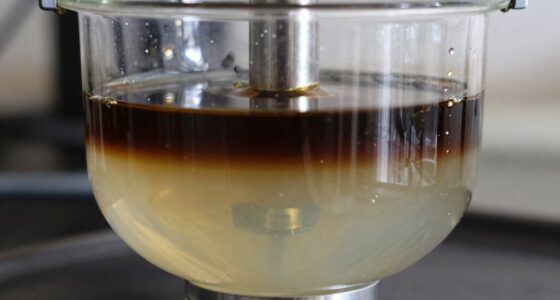

Change Gear Oil

Changing the gear oil is a crucial step in preparing your outboard for both winter and summer seasons. Fresh gear oil ensures proper lubrication and prevents corrosion, especially when using oil filters designed to trap debris. Before draining, warm the oil slightly to help it flow more easily. Remove the drain plug and let the old oil drain completely. Check and replace the oil filter if needed, as a clean filter maintains peak performance. When refilling, consider adding fuel additives that prevent corrosion and improve lubrication. Be sure to fill with the correct gear oil type specified by your manufacturer. Proper gear oil maintenance reduces wear and extends your outboard’s lifespan, ensuring it runs smoothly when you need it most.

Inspect and Cover

Inspecting your outboard thoroughly is essential to guarantee it’s ready for seasonal changes, whether you’re heading into winter or summer. Start by checking for signs of corrosion and corrosion prevention measures, especially around the propeller and electrical connections. Next, examine the fuel system for leaks, stale fuel, or clogs, ensuring proper winterization or summer readiness. Finally, inspect the cover and ventilation to protect against dust, debris, and moisture. To optimize your preparation, consider these steps:

- Clean and apply anti-corrosion treatment on metal surfaces

- Drain or stabilize the fuel system to prevent gumming or freezing

- Cover the outboard with a breathable cover to prevent moisture buildup and damage

This thorough inspection helps maintain your outboard’s performance and longevity through seasonal transitions.

Common Outboard Problems: Signs You Need Service and How to Fix Them

Understanding the signs of common outboard problems is essential to keeping your engine running smoothly. If your boat is experiencing trouble starting or stalls unexpectedly, it could be a fuel system issue. Check for clogged filters, fuel leaks, or dirty carburetors, which can cause poor performance. Electrical issues often manifest as difficulty in ignition, inconsistent spark, or electrical components not functioning. Corrosion or worn wiring can disrupt the flow of electricity, leading to starting problems or failure to run. If you notice abnormal vibrations, overheating, or reduced power, address these issues promptly. Regular maintenance, such as cleaning fuel filters and inspecting wiring connections, can prevent major repairs. Recognizing these signs early guarantees you can fix problems before they escalate, keeping your outboard reliable on the water.

Best Practices for Organizing Your Outboard Maintenance Log

Keeping your outboard maintenance organized is essential for guaranteeing reliable performance and simplifying future repairs. To do this effectively, maintain a detailed record keeping system that tracks all maintenance activities. Use a dedicated maintenance checklist to stay on top of scheduled tasks and inspections. Consider these best practices:

- Regularly update your log after each maintenance session to document what was done and when

- Categorize entries by task type, date, and parts replaced for easy reference

- Use clear labels and consistent formats to ensure quick understanding of the log’s contents

A well-organized maintenance log helps you identify patterns, plan upcoming service, and avoid costly repairs. Prioritizing record keeping makes maintenance more manageable and extends your outboard’s lifespan.

Expert Tips to Stay Ahead With Outboard Maintenance

Staying ahead with outboard maintenance means sticking to regular inspection routines so you catch issues early. Make sure you’re following proper lubrication practices to keep parts running smoothly. Additionally, schedule timely parts replacements to prevent costly breakdowns and keep your motor in top shape.

Regular Inspection Routines

Regular inspection routines are essential for maintaining your outboard’s performance and preventing costly repairs. Regularly check your marine electronics to ensure all systems operate correctly, especially before heading out. Inspect the fuel system for leaks, clogs, or corrosion, and replace filters as needed to avoid fuel flow issues. Additionally, perform visual checks on the exterior for corrosion or damage, and examine the propeller for dings or entanglements. For a more thorough assessment, consider these steps:

- Test electronic gauges and sensors to verify accuracy

- Inspect fuel lines for cracks or wear

- Examine wiring connections for corrosion or loose contacts

Proper Lubrication Practices

Proper lubrication is key to ensuring your outboard engine runs smoothly and reliably. Regularly applying marine grease to moving parts prevents corrosion and reduces wear, keeping your engine in top shape. When servicing, check and replace oil filters to maintain clean oil circulation, which is essential for engine health. Use high-quality marine grease suited for outboard motors, and apply it to propeller shafts, steering linkages, and other friction points. Always follow the manufacturer’s guidelines for lubrication intervals, as over- or under-lubricating can cause damage. Keep a routine to inspect grease fittings and oil filters during each maintenance session. Proper lubrication practices help extend your engine’s lifespan and minimize downtime, ensuring your boat stays ready for the water.

Scheduled Parts Replacement

To keep your outboard motor performing reliably, proactively replacing key parts before they fail is vital. Regular scheduled parts replacement helps prevent unexpected breakdowns and extends your engine’s lifespan, especially during boat storage periods. Focus on components like spark plugs, water pumps, and fuel filters, which are essential for optimal performance. When replacing these parts, confirm proper engine calibration to maintain efficiency and smooth operation. Additionally, inspect seals and hoses during maintenance to avoid leaks. Proper planning ensures you stay ahead of wear and tear, reducing costly repairs. Remember, timely replacement of worn parts not only improves reliability but also enhances safety on the water. Taking these precautions means your outboard stays ready, whether stored or in use.

Frequently Asked Questions

What Are the Signs of an Impending Outboard Motor Failure?

You’ll notice signs of impending outboard motor failure through sensor warnings and unusual noises. If sensors alert you to issues, don’t ignore them; they signal potential problems. Unusual sounds like knocking or sputtering also indicate trouble. Pay attention to changes in performance, overheating, or vibrations. Addressing these signs early can prevent major breakdowns, ensuring your motor stays reliable and safe on the water.

How Do I Troubleshoot Common Electrical Issues in My Outboard?

Imagine your outboard as a heartbeat, steady but sensitive to disruptions. To troubleshoot electrical issues, start by checking the battery for corrosion or weak charge, as battery issues often cause startup problems. Next, inspect wiring for loose connections, corrosion, or fraying that could interrupt power flow. Use a multimeter to test circuits, ensuring consistent voltage. Addressing these areas helps restore your motor’s essential signals and keeps your boat running smoothly.

Can I Perform Maintenance Tasks Myself or Should I Hire a Professional?

You can perform many maintenance tasks yourself with some DIY tips, saving money and gaining satisfaction. However, for complex issues or if you’re unsure, it’s best to hire professional services to guarantee safety and proper care. Regularly inspecting and cleaning your outboard is manageable on your own, but tasks like engine repairs or electrical work should be left to experienced technicians to avoid costly mistakes. Always know your limits.

What Tools and Supplies Are Essential for Outboard Maintenance?

You’ll need essential tools like wrenches, screwdrivers, and pliers, plus supplies such as replacement fuel filters and spark plugs. These items help you perform routine maintenance like changing filters and spark plugs to keep your outboard running smoothly. Having a maintenance manual on hand can guide you through the process. With the right tools and supplies, you can handle basic tasks yourself and save money on professional services.

How Do Weather Conditions Affect Maintenance Schedules and Procedures?

Weather conditions considerably impact your maintenance schedule. During seasonal storage, you need to prepare your outboard for cold or wet weather by applying corrosion prevention measures, like anti-corrosion spray. In humid or rainy conditions, you should frequently check for corrosion and moisture buildup, adjusting your maintenance routine accordingly. Extreme heat or cold also affects lubrication and battery care, so stay vigilant to keep your outboard in top shape year-round.

Conclusion

Keeping up with your outboard maintenance not only prevents unexpected breakdowns but also guarantees your boat runs smoothly when you hit the water. By sticking to a schedule, you catch problems early and extend your motor’s lifespan. Coincidentally, the more consistent you are with checks and service, the more enjoyable your boating adventures become. So, stay proactive, document everything, and let your outboard keep pace with your passion for the water.