Bilge water can come from various sources like engine leaks, hull cracks, or poor maintenance of sanitation systems. To find leaks, you should inspect hoses, fittings, and seals for moisture, rust, or cracks, and monitor pump activity for unusual patterns. Using tools like dye tracers, acoustic detectors, or visual checks helps pinpoint the exact location. Addressing issues early prevents costly repairs and improves safety—keep exploring to learn more about effective detection methods.

Key Takeaways

- Bilge water often originates from leaks in engine, cooling, or fuel systems, and natural hull seepage.

- Visual inspections reveal stains, rust, or corrosion indicating possible leak sources.

- Monitoring bilge pump activity and water chemistry helps identify abnormal water ingress.

- Using tools like dye tracers, acoustic detectors, or hydrophones pinpoints hidden leaks.

- Regular maintenance and inspections prevent leaks, ensuring early detection and vessel safety.

What Are the Main Causes of Bilge Water on Boats?

Bilge water often accumulates on boats because of various operational and structural issues. One common cause is leaks from the engine, fuel, or cooling systems, which introduce fluids into the bilge. Poor maintenance can lead to blocked or malfunctioning marine sanitation devices, causing wastewater to collect in the bilge instead of being properly managed. Additionally, minor cracks or corrosion in the hull or fittings allow water to seep in naturally. Regular inspections of marine sanitation systems can help detect and address issues before they lead to significant bilge water buildup. Proper bilge water management practices are essential not only for environmental compliance but also for maintaining vessel safety and longevity. Understanding bilge water handling procedures can also help prevent environmental contamination and extend the lifespan of your vessel. Being aware of essential oils for marine health may seem unrelated, but some boaters use natural products to maintain onboard air quality and reduce chemical exposure, contributing to overall vessel maintenance. Regulations governing bilge water handling, such as bilge water regulations, require boaters to prevent pollution by managing these discharges properly. Failing to comply can result in hefty fines.

How Does Bilge Water Signal Leaks or Mechanical Issues?

When you notice an increase in bilge water, it often indicates underlying leaks or mechanical problems that need attention. Bilge water can be a sign that leak detection is necessary to prevent further damage. Mechanical issues like worn seals, corroded fittings, or fractured hoses often cause this buildup. By observing the characteristics of the bilge water, you can identify potential problems. Use this quick reference:

| Sign of Leak | Possible Cause | Action Needed |

|---|---|---|

| Water persists after pump | Faulty seal or fitting | Inspect and replace |

| Oil or fuel in bilge | Mechanical failure | Conduct leak detection |

| Sudden water increase | Leaking pipe or hose | Trace and repair |

This table helps you pinpoint issues quickly, ensuring prompt maintenance and safe operation. Recognizing mechanical issues early can also help prevent more costly repairs down the line. Regular inspections and understanding leak sources can significantly reduce the risk of unexpected breakdowns. Additionally, being aware of signs of leaks can aid in quicker diagnosis and resolution. Moreover, implementing a routine inspection schedule can further enhance leak prevention efforts. Staying vigilant about preventative maintenance can ultimately save time and money.

How Can You Detect Bilge Water Accumulation Early?

You can catch bilge water buildup early by regularly inspecting the bilge area for any signs of excess moisture or debris. Monitoring your bilge pump data helps you spot unusual activity that indicates water accumulation. Combining visual checks with pump performance analysis guarantees you stay ahead of potential issues. Additionally, understanding drone-based mapping techniques can aid in inspecting hard-to-reach areas of your vessel for leaks or moisture buildup. Implementing advanced leak detection methods can further improve early identification and prevent costly damage. Being aware of sensor technology can also enhance your ability to detect even minor leaks before they escalate.

Visual Inspection Techniques

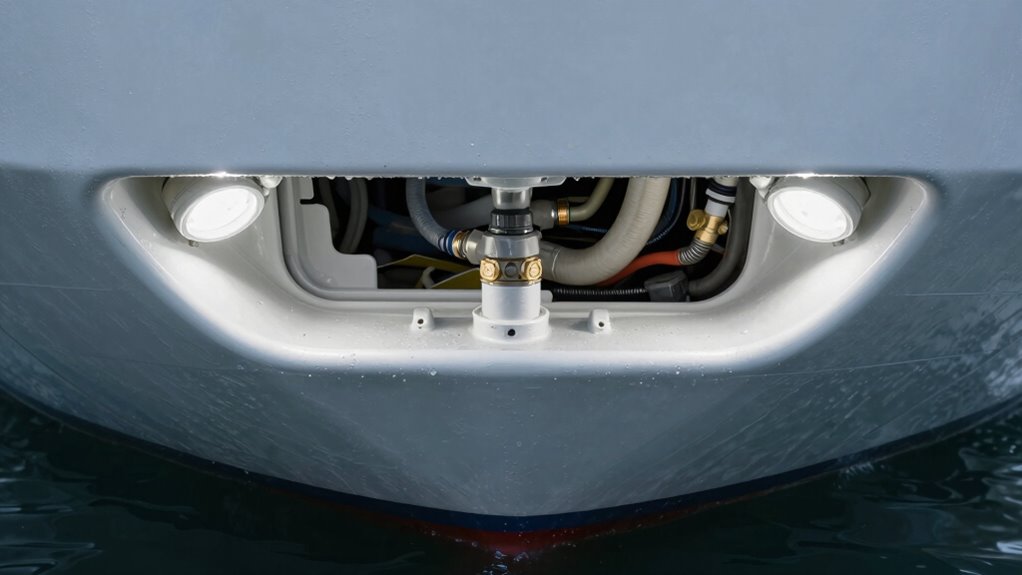

Early detection of bilge water accumulation relies heavily on careful visual inspections, which can reveal signs of water presence before it becomes a serious problem. Look for water stains, rust, or corrosion on the boat hull materials and around fittings. Check for signs of bilge water chemistry changes, such as unusual odors or discoloration. Regularly inspect the bilge area for dampness or accumulation, especially in hard-to-reach spots. Use a flashlight to identify hidden leaks or moisture. Keep an eye on the condition of hoses, seals, and fittings, as deterioration can lead to leaks. Additionally, understanding material deterioration can help identify early signs of structural issues that may contribute to leaks. Recognizing regional flavors and regional materials can also provide insight into how different environments might accelerate material wear and corrosion, aiding in proactive maintenance. Performing routine maintenance checks can further prevent unexpected leaks and extend the lifespan of boat components.

Monitoring Bilge Pump Data

Monitoring bilge pump data provides a reliable way to detect water accumulation before it becomes a major issue. By regularly reviewing pump activity, you can identify unusual patterns that indicate potential leaks or excess bilge water. Modern bilge water management systems often include sensors and digital monitors that record pump cycles, flow rates, and water levels. These leak detection techniques help you catch problems early, allowing for prompt maintenance and preventing costly damage. Pay attention to increased pump activity or frequent cycling, which signals water buildup. Consistent data analysis helps you maintain a dry bilge area and ensures your vessel’s safety. Implementing these monitoring methods enhances your overall bilge water management strategy and minimizes the risk of unexpected leaks.

What Tools and Techniques Help Find Hidden Leaks?

To find hidden leaks, you can use specialized tools like acoustic leak detectors that listen for sound anomalies. Visual inspection techniques, such as examining suspect areas closely, also play a crucial role. Additionally, dye tracers can reveal leaks by marking the flow of water, making hidden issues easier to spot. Being aware of the pinball machine weight can also assist in identifying unusual vibrations or sounds that may indicate leaks or structural issues. Regular monitoring of dog health and wellness can help catch early signs of water damage or leaks affecting the environment. Incorporating the use of recycled materials in certain detection devices can further enhance eco-friendly leak detection methods. Employing advanced sensing technology can improve detection accuracy and reduce the time needed to locate elusive leaks. Furthermore, utilizing lab-grade measurement tools ensures precise readings during the inspection process, helping to identify the source of leaks more reliably.

Acoustic Leak Detection

Acoustic leak detection relies on specialized tools and techniques that can identify the sound of leaks even when they’re hidden from plain sight. By listening for the leak sound, you can locate the precise source of water escape. These methods detect the sound wave generated by a leak, which travels through pipes or hull structures. Using sensitive microphones and listening devices, you can pick up even faint leak sounds.

- Handheld acoustic sensors for pinpointing leaks

- Hydrophones for underwater sound detection

- Amplifiers to enhance leak sound signals

- Data loggers for continuous monitoring

- Noise filtering to differentiate leak sound from background noise

Visual Inspection Techniques

When searching for hidden leaks, visual inspection techniques are essential tools that can reveal issues not detectable by sound alone. You should start by carefully examining the bilge area for signs like wetness, corrosion, or staining, which could indicate a leak. Using a flashlight helps spot cracks or holes in the hull or fittings. A mirror can assist in inspecting hard-to-reach spots. Incorporate your knowledge of marine biology—look for signs of mold or algae buildup caused by persistent moisture. Understanding nautical history also offers insights into common weak points or aged components prone to leaks. Regularly check hoses, seams, and fittings for deterioration. Additionally, inspecting body jewelry measurements and materials can help identify corrosion or incompatibility issues that may contribute to leaks. Combining these careful visual assessments with your understanding of the vessel’s design helps pinpoint the source of bilge water intrusion efficiently.

Use of Dye Tracers

Dye tracers are highly effective tools for uncovering hidden leaks that are otherwise difficult to detect. By introducing leak detection dyes into suspect areas, you can quickly identify leak sources through color changes or fluorescence. These dye tracer applications work well in bilge water systems, engine compartments, and plumbing lines. When using dye tracers, you add a few drops of leak detection dyes into the suspected leak point or fluid system. Then, observe for color or fluorescence changes indicating a leak. This method saves time and increases accuracy in pinpointing leaks. Proper application techniques ensure the most effective detection results. Proper application also involves understanding electric power generation techniques used to power tools like dye lights or UV lamps, which can enhance leak detection accuracy. – Applying dye directly into suspect areas – Using UV light to detect fluorescence – Combining with pressure tests – Monitoring bilge water for color change – Confirming leaks with dye tracing. Additionally, understanding cabling solutions and proper lighting equipment can improve the visibility of fluorescent dyes during inspection.

How Do You Pinpoint the Exact Leak Location?

Pinpointing the exact leak location in bilge water systems can be challenging, but with the right techniques, it becomes much more manageable. Start by inspecting obvious areas for signs of marine debris or corrosion. Use a moisture meter or dye tracers to trace leaks more precisely. Also, review bilge water regulations to ensure compliance during testing. To stay organized, compare potential leak sources with these common problem spots:

| Possible Leak Source | Inspection Method |

|---|---|

| Hoses and fittings | Visual check, pressure test |

| Seals and gaskets | Touch for moisture, dye test |

| Through-hull fittings | Tightness check |

| Marine debris | Remove debris, inspect fittings |

This systematic approach helps you identify leaks quickly and prevents unnecessary disassembly.

Best Practices for Inspecting Your Boat’s Bilge Area

Regularly inspecting your boat’s bilge area is essential to catch leaks early and maintain safety. A thorough inspection helps with bilge water management and keeps your boat in top condition. Start by checking the bilge for any standing water or moisture, and look for signs of corrosion or corrosion stains. Keep the bilge clean and free of debris to make leaks easier to spot. Use a flashlight to see into dark corners and verify that all bilge pumps are functioning properly. Incorporate bilge inspections into your boat maintenance routines to prevent small issues from becoming major problems.

Regularly check your boat’s bilge for leaks, corrosion, and pump function to ensure safety and proper maintenance.

- Check for wetness or water accumulation

- Look for oil or fuel residue

- Verify bilge pump operation

- Inspect hoses and fittings for leaks

- Clean the bilge regularly

How to Differentiate Normal Bilge Water From Problematic Leaks?

Understanding the difference between normal bilge water and problematic leaks is key to maintaining your boat’s safety. Normal bilge water often contains minimal contamination from routine condensation or minor spills. In contrast, problematic leaks usually involve persistent or unusual sources, like engine coolant, oil, or fuel, indicating a serious issue. To distinguish, check for signs such as oily or colorful bilge water, foul odors, or greasy residues. Regularly inspecting and testing your bilge water can prevent contamination that complicates bilge water disposal. Here’s a quick comparison:

| Aspect | Normal Bilge Water | Problematic Leaks |

|---|---|---|

| Contamination Level | Low, mostly clean | High, greasy or foul |

| Odor | Slight or none | Strong, chemical, or fuel smell |

| Source | Condensation, minor spills | Engine leaks, fuel, oil |

What Are the Next Steps After Discovering a Leak?

Once you’ve found a leak, the first step is to assess how severe it is and whether it needs immediate attention. Next, isolate the affected area to prevent further damage or water intrusion. Finally, plan your repair strategy to fix the leak efficiently and prevent future issues.

Assess Leak Severity

How do you determine the severity of a bilge water leak? Start with a thorough leak assessment to gauge how serious the problem is. Evaluate factors like the leak’s size, frequency, and whether it’s worsening. Check if the leak affects critical systems or if it’s localized. Monitoring the leak over time helps identify if it’s stable or escalating. You should also consider the potential damage and safety risks involved.

- Measure the leak’s volume and rate

- Identify the location and source

- Track leak progression over time

- Assess impact on boat stability and safety

- Determine if immediate action is needed

This process helps you prioritize repairs based on leak severity, ensuring safe and effective maintenance.

Isolate Affected Area

When you discover a bilge water leak, the immediate priority is to isolate the affected area to prevent further damage and contain the problem. Quickly shutting off pumps and closing valves around the leak helps maintain marine safety and limits environmental impact. Use barriers or absorbent materials to contain any ongoing spills, especially if hazardous substances are involved. Communicate with your crew to ensure everyone stays clear of the affected zone. Mark the area clearly and restrict access until further inspection. Properly isolating the leak reduces the risk of water entering critical systems and minimizes the chance of spreading pollutants into the environment. Staying calm and acting swiftly ensures safety and helps protect marine life and your vessel’s integrity.

Plan Repair Strategy

After isolating the affected area, your next step is to develop a clear repair plan to address the leak effectively. Start by reviewing bilge water regulations to ensure compliance during repairs. Check your boat maintenance schedules to determine if any routine inspections or parts replacements are overdue. Prioritize sourcing the right repair materials and tools. Consider whether professional assistance is needed or if you can handle the repair yourself. Document the process for future reference and compliance. Planning ahead minimizes downtime and prevents recurring leaks. Staying organized ensures your boat remains seaworthy and compliant with environmental standards. A well-structured repair plan helps you address the leak quickly, safely, and efficiently, protecting your vessel and the marine environment.

- Assess damage severity and necessary repairs

- Gather required tools and materials

- Schedule repairs around boat maintenance routines

- Review bilge water regulations to ensure compliance

- Decide if professional help is needed

How Regular Maintenance Prevents Excess Bilge Water and Leaks?

Regular maintenance plays a crucial role in preventing excess bilge water and leaks on your vessel. Staying on top of inspections guarantees that potential issues are caught early, reducing the risk of violations related to bilge water regulations. Properly maintained engines, pumps, and seals help prevent leaks that can lead to water accumulation. Plus, following routine checks supports boating safety by minimizing hazardous conditions. Here’s a quick overview:

| Maintenance Task | Frequency | Key Benefit |

|---|---|---|

| Inspect bilge pumps | Monthly | Ensures reliable operation |

| Check for leaks | Before each trip | Prevents water buildup |

| Clean bilge area | Every 3-6 months | Reduces odors and corrosion |

Consistent upkeep keeps your vessel compliant and safe, avoiding costly repairs and regulatory issues.

Why Addressing Bilge Water Issues Quickly Saves Money and Ensures Safety?

Addressing bilge water issues promptly can save you significant money and prevent dangerous situations on your vessel. Ignoring leaks or overflows can lead to costly repairs, engine damage, and increased fuel consumption. Quick action also enhances marine safety by reducing the risk of fire or sinking caused by accumulated water. Additionally, timely repairs minimize the environmental impact, preventing contaminated water from polluting oceans and waterways.

- Prevents costly repairs and engine damage

- Maintains vessel stability and safety

- Reduces risk of fire or sinking incidents

- Limits environmental pollution and legal liabilities

- Ensures compliance with marine safety regulations

Dealing with bilge water issues fast protects your crew, vessel, and the environment, making your journeys safer and more economical.

Frequently Asked Questions

Can Bilge Water Contain Hazardous or Toxic Substances?

Yes, bilge water can contain hazardous materials and toxic substances, especially if your boat has leaks or if you’ve used chemicals nearby. These dangerous substances can leak into the bilge, making it risky to handle without proper precautions. You should always test and treat bilge water before disposal. Wearing protective gear and following environmental regulations helps prevent pollution and protects your health from exposure to toxic substances.

How Often Should Boat Bilge Systems Be Inspected?

You should inspect your boat’s bilge system at least once a month. During these inspections, perform bilge pump maintenance to ensure the pump operates correctly, check for debris, and verify bilge sensor calibration to detect water accurately. Regularly inspecting and maintaining your bilge system helps prevent leaks, reduces hazardous water buildup, and keeps your boat safe and in good working order.

What Are the Environmental Regulations Regarding Bilge Water Disposal?

You must comply with environmental regulations that prohibit discharging untreated bilge water into waters to prevent marine pollution. Regulations like the MARPOL Annex I set strict standards for bilge water disposal, requiring treatment before release. You need to monitor, maintain, and document your bilge systems regularly to guarantee compliance standards are met. By doing so, you actively protect marine environments and avoid hefty penalties for illegal discharges.

Are There Any DIY Methods to Prevent Bilge Water Buildup?

Yes, you can prevent bilge water buildup with DIY methods. Install a DIY bilge pump to regularly remove water before it accumulates. Use bilge water filters to catch debris and prevent pollution. Regularly check and maintain these filters and pump to guarantee they work efficiently. Keep the bilge area clean, and address leaks promptly to reduce the chances of water buildup, making your boat safer and eco-friendly.

How Do Seasonal Changes Affect Bilge Water Levels?

Seasonal changes can considerably affect your bilge water levels. Temperature fluctuations cause metal expansion and contraction, potentially creating new leaks or worsening existing ones, leading to more water in the bilge. Precipitation impacts, like rain or snow, increase water ingress, especially if your boat’s seals aren’t tight. To manage this, routinely check for leaks and drain your bilge more often during rainy or cold seasons, preventing buildup caused by seasonal shifts.

Conclusion

By mastering methods to monitor, measure, and manage bilge water, you’ll minimize messes, mitigate malfunctions, and maintain your boat’s essential beauty and balance. Regular checks and swift solutions serve as shields, safeguarding your sea adventures. Stay vigilant, vigilant, and vigilant—your proactive approach prevents problems before they surface. With dedication and decisive action, you’ll keep your vessel’s crucial vessel in pristine condition, ensuring smooth sailing and safer seas for every voyage ahead.