To guarantee leak-free, secure hose connections, it’s best to use the double-clamp rule by installing two clamps around each fitting—one behind and one in front of the fitting or barb. Properly position the clamps about 1/4 inch from the hose ends, evenly tighten them, and choose corrosion-resistant stainless steel clamps of the correct size. Correct installation and maintenance are key to preventing leaks and damage—keep exploring to master these essential practices.

Key Takeaways

- Using two clamps enhances security and prevents leaks compared to a single clamp.

- Proper clamp positioning—about 1/4 inch from hose ends—is essential for effective sealing.

- Select stainless steel clamps that match hose size and resist corrosion for durability.

- Evenly tighten both clamps using appropriate tools to avoid hose damage and ensure a secure fit.

- Regular inspection and maintenance help detect issues early, prolonging hose lifespan and system reliability.

What Is the Double-Clamp Rule and Why Is It Important?

The double-clamp rule is a best practice that guarantees a secure and leak-free connection when installing hose clamps. By using two clamps instead of one, you reduce the risk of leaks, especially in critical systems. When selecting clamps, consider the hose material, as some materials are more flexible or prone to deformation. Proper clamp torque is essential; too tight can damage the hose, while too loose can cause leaks. Applying the correct torque ensures a snug fit without compromising the hose’s integrity. This approach provides added security, especially in high-pressure or vibration-prone environments. Additionally, understanding the fabric decorating markers can help in marking or identifying hose connections during installation or maintenance. Proper clamp installation is crucial to avoid system failures and maintain optimal performance. Using the double-clamp rule consistently also helps in early detection of potential issues, saving time and cost in repairs. Properly tightening clamps ensures they stay secure over time and resist loosening due to vibrations. Following the double-clamp rule helps prevent failures, prolongs hose lifespan, and maintains system reliability, making it an essential practice for effective hose connection management. Incorporating visual inspection techniques can further enhance system safety and performance over time.

Why Using Just One Clamp Can Lead to Leaks and Failures

Relying on just one clamp to secure a hose may seem sufficient, but it often leads to leaks and potential failures. When only one clamp is used, the clamp material might not provide enough strength or flexibility for the specific application. If the clamp material isn’t compatible with the hose or the fluid it carries, corrosion or deterioration can occur, compromising the seal. Additionally, a single clamp may be poorly positioned or too loose, allowing leaks to develop under pressure or vibration. Hose compatibility is vital; using the wrong clamp material can cause damage or failure over time. A double-clamp setup distributes pressure more evenly and offers a more secure, leak-proof connection, reducing the risk of failures caused by material mismatch or improper installation. Proper maintenance routines and inspection can help identify issues before they lead to significant failures. Implementing the double-clamp rule is a simple yet effective way to ensure a reliable connection in various applications. Ensuring clamp installation best practices adhere to manufacturer guidelines further enhances connection reliability. Employing correct installation techniques can further prevent issues caused by improper tightening or positioning. Moreover, understanding the material properties of clamps can significantly improve long-term performance and durability.

How to Properly Position and Install Double Clamps for a Secure Seal

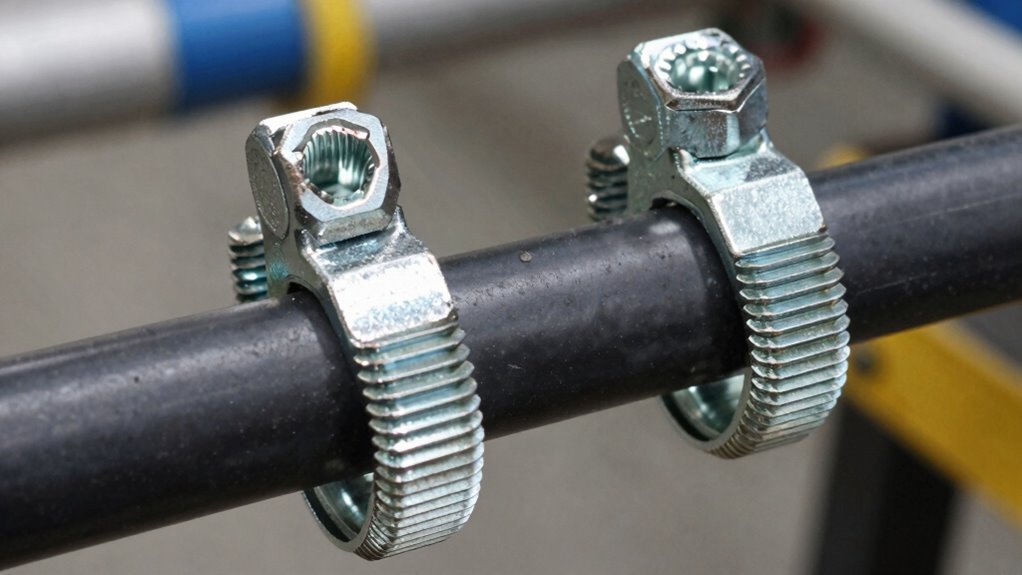

To guarantee a secure seal when installing double clamps, proper positioning is essential. First, choose the correct hose clamp sizing to match your hose diameter, ensuring a snug fit without over-tightening. Position the clamps about 1/4 inch from the end of the hose to prevent slipping or leaks. Place them evenly spaced around the hose, with one clamp just above the fitting and the other slightly below, creating a double layer of security. When selecting clamp material, opt for corrosion-resistant options like stainless steel for durability. Tighten each clamp gradually, ensuring they compress the hose evenly against the fitting. Proper positioning and installation techniques of double clamps reduce the risk of leaks and failure, providing a reliable, long-lasting seal. Being mindful of clamp tension and applying the correct amount of torque can also help prevent damage to the hose and ensure a lasting connection. Additionally, understanding clamp placement principles can help optimize the sealing effectiveness. Incorporating proper maintenance practices can extend the lifespan of the clamps and prevent future issues. Understanding clocks/time travel and their symbolism can remind you of the importance of timing and precision in your work.

Choosing the Best Hose Clamps: Material, Size, and Type Tips

Selecting the right hose clamp involves considering the clamp material, size, and type that best suit your application. For clamp material, choose stainless steel for durability and corrosion resistance, especially in harsh environments. For less demanding jobs, zinc-plated steel can work, but it may corrode over time. The size should match your hose diameter closely—measure accurately to guarantee a snug fit without damaging the hose. Using a clamp that’s too small can cause leaks, while an oversized clamp may slip or fail to secure properly. The type of clamp also matters; worm-gear clamps are versatile, but spring clamps provide even pressure. Additionally, understanding the future societal impacts of technology can help you make more informed choices about materials and design, ensuring long-term reliability and sustainability. Considering material corrosion resistance when selecting clamps can significantly extend their service life and reduce maintenance needs. Incorporating environmentally friendly materials into your selection process can further support sustainable practices and minimize ecological footprint. An often overlooked factor is body jewelry measurements, which is crucial for ensuring proper fit and function in specialized applications. By matching these factors, you’ll ensure a secure, long-lasting connection suited to your specific hose and application needs.

Common Mistakes When Installing Double Clamps: and How to Avoid Them

When installing double clamps, it’s easy to make mistakes that compromise their effectiveness. Over-tightening can damage hoses, while incorrect placement can lead to leaks or failure. Regularly inspecting your clamps helps catch issues early before they cause bigger problems. Understanding testing accuracy methods can also help ensure your clamps are functioning properly over time. Additionally, using the correct tools, such as appropriate torque tools, can help prevent over-tightening and ensure proper installation. Being aware of proper clamp positioning can further enhance the reliability of your setup. Incorporating proper maintenance practices into your routine can extend the lifespan of your clamps and prevent future issues.

Over-tightening Risks

Have you ever tightened a hose clamp so much that it nearly crushed the hose? Over-tightening risks damaging both the hose and the clamp. Excessive clamp tension can deform the hose, causing leaks or failures. It’s essential to match the clamp’s tension to the hose’s material and diameter to avoid damage. Use a torque wrench if possible, and tighten just enough to secure a leak-free seal. Over-tightening can also strip threads or break the clamp, leading to costly repairs. Always consider hose compatibility and clamp tension during installation. Here’s a quick guide:

| Clamp Tension Level | Effect on Hose |

|---|---|

| Too tight | Deforms/harm hose |

| Ideal | Secure, leak-free |

| Too loose | Leaks, slippage |

| Excessive force | Damages clamp, hose |

| Just right | Proper seal |

Incorrect Clamp Placement

Incorrect clamp placement is a common mistake that can compromise the effectiveness of your hose connection. Poor clamp positioning often results from installation errors, such as placing the clamp too far from the end of the hose or in the wrong spot on the fitting. When clamps aren’t positioned correctly, they may not seal properly, leading to leaks or hose slippage. Verify you position the clamp over the designated area, usually about a quarter-inch from the end of the hose, and tighten evenly. Avoid rushing the process or relying solely on visual cues. Proper installation requires careful attention to clamp placement to maintain a secure, leak-free connection. Correct clamp positioning is essential for the double-clamp rule to work effectively and prevent future issues.

Neglecting Proper Inspection

Neglecting proper inspection during double clamp installation can lead to serious issues like leaks and hose failure. You might overlook signs of hose wear or clamp corrosion, risking performance. Always check the clamp material compatibility with your hose to prevent corrosion and degradation. Inspect the clamps for tightness, proper placement, and signs of corrosion or damage. Ensure the clamps are evenly spaced and seated correctly. Here’s a quick guide:

| Inspection Step | What to Look For | Why It Matters |

|---|---|---|

| Clamp Material Compatibility | Corrosion or incompatible metals | Prevents hose failure |

| Tightness and Placement | Loose or uneven clamps | Ensures a secure seal |

| Hose Condition | Cracks, wear, or leaks | Avoids future leaks |

Regular inspections keep your system reliable and safe.

A Step-by-Step Guide to Double Clamping for Leak-Free Connections

To guarantee a leak-free connection, double clamping is a reliable technique that provides extra security for hose fittings. Start by selecting the right clamp material suitable for your application, such as stainless steel for durability. Gather your installation tools, including a screwdriver or wrench. First, position the initial clamp just behind the barb or fitting, ensuring it’s snug but not overly tight. Then, place the second clamp slightly ahead of the first, covering the same hose section. Tighten both clamps evenly, avoiding over-tightening that could damage the hose. Remember to check for proper fit and securement. This method minimizes leaks and enhances connection strength, especially in high-pressure systems.

Double clamping ensures leak-free, secure hose connections with even tightening and proper placement.

- Proper clamp placement

- Consistent tightening

- Regular inspection

How Double Clamps Improve Longevity and Safety in Hose Connections

Double clamping not only guarantees a leak-free connection but also considerably extends the lifespan of hose fittings. When you use double clamps, you distribute pressure evenly across the hose material, reducing wear and preventing damage caused by over-tightening. This is especially important when working with different hose materials, as some are more susceptible to crushing or cracking. Ensuring clamp compatibility with your hose material helps avoid issues like corrosion or deterioration over time. Proper double clamping minimizes movement and vibration, which can weaken connections and cause leaks or failures. Overall, this practice enhances safety by maintaining secure, durable connections, reducing the need for frequent replacements, and preventing potential hazards caused by hose failure.

Troubleshooting Leaks and Fixing Clamping Problems

When you notice leaks or signs of pressure loss in your hose connections, it’s essential to identify the root cause promptly. Leaks often stem from improper clamp size, inadequate tightening, or incompatible hose material. First, check if the clamp fits the hose properly—too small or large clamps won’t seal correctly. Next, inspect the hose material; some materials are more prone to wear or cracking under pressure. Finally, ensure the clamp is tight enough without over-tightening, which can damage the hose. To troubleshoot effectively, consider these points:

- Verify clamp size matches the hose diameter

- Inspect hose material for cracks or wear

- Adjust clamp tension appropriately without over-tightening

Tips for Maintaining and Inspecting Your Hose Clamps Over Time

To keep your hose clamps in good shape, establish a regular inspection schedule. Make sure you’re adjusting clamps properly to maintain a secure fit without overstressing the material. Consistent checks help catch issues early and guarantee everything stays tight and functional.

Regular Inspection Schedule

Regularly inspecting your hose clamps is essential to guarantee they stay secure and function properly over time. Establishing a routine inspection schedule helps catch issues early, preventing leaks or failures. During inspections, check the hose material for cracks or deterioration, as worn material can compromise the seal. Ensure the clamp size remains appropriate for the hose, avoiding over-tightening or looseness. Regular checks also involve tightening any loose clamps to maintain a secure fit. By sticking to a consistent schedule, you reduce the risk of unexpected failures and extend the lifespan of your hose system.

- Regularly verify hose material integrity and signs of wear

- Confirm clamp size matches the hose for a snug fit

- Tighten any loose clamps to maintain secure connections

Proper Adjustment Techniques

Proper adjustment of your hose clamps is essential for ensuring a secure and leak-free connection over time. To maintain effectiveness, regularly check that the clamp size matches the hose material and application. Tighten the clamp enough to prevent leaks but avoid over-tightening, which can damage the hose or deform the clamp. Use a screwdriver or pliers suited for the clamp type to achieve consistent tension. Over time, clamps can loosen or corrode, so inspect for rust, cracks, or signs of wear.

| Hose Material | Clamp Size | Adjustment Tip |

|---|---|---|

| Rubber | Correct size | Tighten gradually, check for leaks |

| PVC | Slightly larger | Do not over-tighten |

| Silicone | Proper fit | Regularly inspect for corrosion |

| Reinforced | Exact size | Avoid deforming the clamp |

Frequently Asked Questions

Can Double Clamps Be Used With Flexible or Rigid Hoses?

Yes, you can use double clamps with both flexible and rigid hoses. Just make certain material compatibility to prevent corrosion or damage, and select the right clamp size for a secure fit. For flexible hoses, double clamps provide extra security against leaks, while with rigid hoses, they help maintain a tight seal. Always verify that the clamps match your hose’s diameter for peak performance and durability.

Is There a Specific Torque Setting Recommended for Double Clamps?

Think of tightening a clamp like tuning a vintage radio—precision matters. For double clamps, there’s no universal torque setting since it depends on clamp material and hose type. You should use appropriate tightening tools, like a screwdriver or wrench, and tighten until the clamp feels snug without over-tightening, which could damage the hose or clamp. Always follow manufacturer recommendations for specific torque values to guarantee a secure, leak-free connection.

How Often Should Hose Clamps Be Inspected or Replaced?

You should inspect your hose clamps at least every 6 to 12 months to guarantee maximum clamp longevity and maintain a secure connection. Replace clamps immediately if you notice corrosion, rust, or if they become loose or damaged. Regular inspections help prevent leaks and failures. By staying vigilant and following a consistent inspection frequency, you assure your system stays secure, and your hose clamps perform reliably over time.

Are There Environmental Conditions That Affect Clamp Performance?

Ever wonder how environmental conditions impact your hose clamps? You should know that factors like humidity, salt exposure, and extreme temperatures can reduce their corrosion resistance and temperature tolerance. These conditions cause rust and weaken the clamp’s grip over time. To guarantee peak performance, choose clamps designed for harsh environments, and regularly inspect them. Don’t let weather compromise your system’s integrity—select the right materials and maintain them properly.

Can Double Clamps Be Reused After Removal or Disassembly?

Yes, you can reuse double clamps after removal or disassembly if they’re made from compatible materials and have good corrosion resistance. Check for signs of wear, corrosion, or deformation before reusing them. Confirm the clamp material matches the application’s environmental conditions, especially if exposed to moisture or chemicals. Proper cleaning and inspection help maintain their integrity, making reuse safe and effective without compromising the sealing or performance.

Conclusion

By following the double-clamp rule, you’re building a fortress around your hose connections, preventing leaks and failures. Proper placement, choosing the right clamps, and regular inspections keep your system running smoothly like a well-oiled machine. Remember, a secure connection isn’t just a detail—it’s the backbone of safety and longevity. Stick to these best practices, and your hoses will stand strong, weathering the storms of time with resilience and confidence.