Trailer bearings are essential for smooth, safe wheel rotation and to support your load. Regular inspections, proper lubrication, and timely replacements help prevent wear, overheating, and failure. Watch for signs like noises, excessive heat, or hub wobbling. Keep an eye on possible causes like overloading or dirt intrusion. Staying proactive with maintenance can save you costly repairs and safety issues. If you want to learn how to catch problems early and keep your trailer rolling smoothly, there’s more to discover.

Key Takeaways

- Regularly inspect hub temperature, noises, and wheel play to detect early bearing issues.

- Maintain proper lubrication with high-quality grease to prevent friction, heat buildup, and contamination.

- Avoid overloading the trailer beyond manufacturer-specified weight limits to prevent bearing overheating and failure.

- Look for signs like abnormal vibrations, hub discoloration, or excessive heat during operation.

- Follow manufacturer guidelines for bearing replacement and use the correct tools for safe, effective maintenance.

Top picks for "trailer bearing catch"

Open Amazon search results for this keyword.

As an affiliate, we earn on qualifying purchases.

What Are Trailer Bearings and Why Do They Matter?

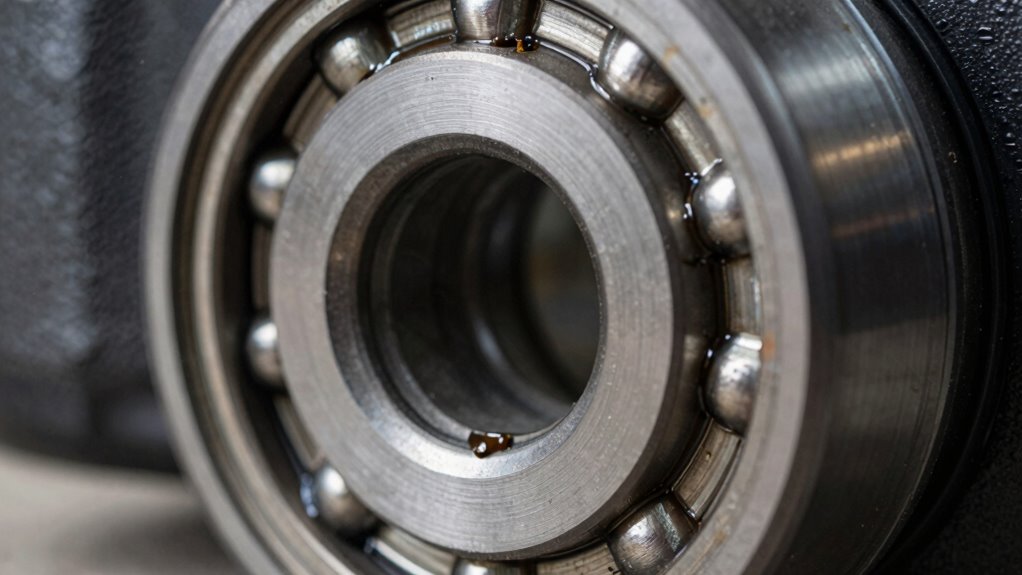

Trailer bearings are small but essential components that allow your trailer’s wheels to spin smoothly and safely. They support the wheel’s rotation and help transfer the load from the trailer to its axle. Proper lubrication techniques are critical to prevent friction and heat buildup, which can damage the bearings. Using the right bearing materials, such as high-quality steel or ceramic, ensures durability and resistance to corrosion. These materials withstand harsh conditions, extending the lifespan of your bearings. Regular maintenance, including proper lubrication, keeps the bearings functioning properly. Without well-maintained trailer bearings, you risk wheel failure, uneven tire wear, or even accidents. Additionally, understanding the contrast ratio helps in selecting projectors that deliver deep blacks and bright whites, which is essential for clear, vibrant visuals in any setting. Remember, these tiny parts play a crucial role in your trailer’s safe and efficient operation, and staying informed about bearing materials can help you choose the best replacements when needed. Proper lubrication practices are vital to ensure the longevity and performance of your trailer bearings, and following manufacturer recommendations can further prevent issues.

How Can You Tell if Your Trailer Bearings Are Wearing Out?

If you notice strange noises like squealing or grinding during your ride, your trailer bearings might be wearing out. You should also check for excessive heat from the hub, which can indicate problems. Paying attention to these signs can help prevent more serious damage and keep your trailer running smoothly. Regularly inspecting and maintaining your cable failures can also help identify issues early before they lead to bearing problems. Additionally, incorporating Free Floating bearings, which allow for better movement and reduced wear, can prolong the life of your trailer components. Proper bearing maintenance is essential practices to extend bearing lifespan and ensure safe towing. Being aware of seasonal changes and how they affect bearing performance can also help you plan timely inspections and replacements. Understanding how regional flavors influence material choices can also improve the durability of your bearings in different environments.

Unusual Noises During Ride

When your trailer bearings start to wear out, you might notice unusual noises during your ride. These sounds are key clues for noise diagnosis and can alert you to bearing issues early. Listen for grinding, humming, or squealing noises that increase with speed or when turning. If you hear these, it’s time for a bearing inspection. Often, worn bearings produce a rhythmic or uneven noise, indicating metal-on-metal contact or imbalance. Ignoring these sounds can lead to bearing failure and costly damage. Regularly check for abnormal noises during your trip, especially when you feel vibrations or hear a droning sound. Catching these warning signs early helps prevent complete seizure and keeps your trailer rolling smoothly. Stay attentive to sounds—your ears are your first line of defense. Additionally, performing proper maintenance techniques such as lubrication and pre-emptive inspections can significantly extend bearing life and improve safety. Being aware of signs of bearing wear can help you address issues before they become serious, including visual signs like discoloration or damage. Recognizing early noise symptoms can make a significant difference in avoiding costly repairs down the line. Regular inspections and preventative maintenance can help you detect issues before they escalate.

Excessive Heat From Hub

Excessive heat from the hub is a clear sign that your bearings may be wearing out. When the hub temperature rises markedly, it indicates increased brake friction or improper lubrication, causing unnecessary stress on the bearings. You might notice the hub feels hot to the touch after a short drive or during stops. Overheating can lead to premature bearing failure or even a seizure if left unchecked. Regularly check the temperature during routine inspections, especially after long hauls or heavy loads. If you detect excessive heat, stop and examine the bearings immediately. Proper bearing lubrication and timely maintenance can prevent overheating. Ignoring this warning can result in costly repairs or dangerous breakdowns, so always stay alert to changes in hub temperature and brake friction signs. Maintaining bearing lubrication with appropriate household products such as proper lubricants and cleaning supplies can help maintain optimal bearing function. Additionally, understanding the bucolic beauty of Saratoga Springs or exploring cultural events in Washington D.C. can provide a welcome break from maintenance routines.

What Causes Trailer Bearings to Fail? Common Issues to Know

Trailer bearings can fail for several reasons, often related to improper maintenance or overloads. If you overload your trailer, you risk putting excessive stress on the bearings, leading to premature failure. Additionally, insufficient lubrication and contamination from dirt and debris can accelerate wear and cause bearings to fail sooner than expected. Regularly inspecting and maintaining your trailer bearings can help prevent these issues and extend their lifespan preventative maintenance. Using high-quality glycolic acid products for cleaning and skin care can also promote overall equipment longevity, including trailer components. Proper installation with quality bearings can also significantly reduce the risk of early failure and ensure smoother operation. Understanding bearing design and how it affects performance can further help in selecting the right components to prevent issues. Paying attention to bearing materials and their compatibility with operating conditions is essential for durability and reliable performance.

Bearing Overloading Risks

Overloading your trailer can put excessive stress on the bearings, leading to premature failure. When you ignore the load capacity, bearing overloading occurs, causing components to work harder than they’re designed for. This added strain can cause overheating, increased wear, and eventual seizing. To avoid these risks, pay close attention to your trailer’s weight limits and distribute loads evenly. Keep in mind:

- Exceeding the load capacity shortens bearing lifespan

- Overloading causes uneven wear and heat buildup

- Sudden weight shifts increase stress on bearings

- Heavy loads accelerate bearing fatigue

- Ignoring weight limits risks costly repairs and downtime

Sticking to recommended load capacities helps prevent bearing overloading, ensuring your trailer operates smoothly and safely. Proper load management is key to avoiding bearing failure.

Insufficient Lubrication Levels

Proper lubrication is essential for keeping your trailer bearings running smoothly. When oil levels are too low, it hampers effective lubrication maintenance, increasing friction and heat. Without enough oil, metal parts grind against each other, leading to accelerated wear and potential bearing failure. Regularly check your lubrication levels to guarantee they meet manufacturer recommendations. Neglecting this can cause the oil to thin out or evaporate over time, leaving the bearings vulnerable. Insufficient lubrication not only causes increased wear but also raises the risk of overheating, which can seize the bearing entirely. To prevent these issues, keep a close eye on your oil levels and top off as needed. Proper lubrication maintenance is the simple step that can save you from costly repairs and downtime. Additionally, understanding AI-driven diagnostic tools can help identify lubrication issues before they lead to serious damage.

Contamination and Dirt

Contamination and dirt are common causes of trailer bearing failure, and they can quickly degrade the system if not addressed. Soil debris can enter the bearings through damaged seals or poor maintenance, causing abrasive wear. Water intrusion is another major issue, leading to rust and corrosion that weaken the bearing components. To prevent these problems, regularly inspect and clean your bearings. Keep an eye out for:

- Dirt buildup around seals

- Signs of water pooling or rust

- Damaged or worn seals

- Excessive dust or soil debris

- Moisture accumulation from leaks

How to Inspect Trailer Bearings to Catch Problems Early

Inspecting your trailer bearings regularly is essential to catching problems before they lead to costly repairs or breakdowns. Start with a visual check for leaks, corrosion, or excessive heat near the hub. Listen for unusual noises during a test drive, like grinding or squealing, which indicate bearing issues. Also, perform a differential inspection by checking for uneven tire wear or misalignment, as these can signal bearing or axle problems. Ensuring proper tire alignment reduces stress on bearings and prolongs their life. Regular lubrication and checking for play in the wheel help identify early wear. Use the table below to remember key inspection aspects:

| Inspection Step | What to Look For | Why It Matters |

|---|---|---|

| Visual Inspection | Leaks, corrosion, heat | Early signs of failure |

| Noise Test | Grinding, squealing | Bearing damage |

| Tire Alignment | Uneven wear | Differential or bearing issue |

| Play in Wheel | Excess movement | Bearing looseness |

| Lubrication Check | Grease presence and quality | Prevents friction damage |

How to Check and Replace Trailer Bearings: A Step-by-Step Guide

Checking and replacing trailer bearings might seem intimidating, but with the right steps, you can do it yourself and save money. First, lift the trailer to access the wheel assembly. Remove the wheel and hub, inspecting bearing materials for wear or damage. Clean the parts thoroughly, checking for proper wheel alignment. If bearings are worn or damaged, replace them with new ones suited to your trailer. When installing, ensure all components are properly lubricated and seated. Reassemble the hub, tighten the axle nut to the manufacturer’s specifications, and replace the wheel. Regularly inspect your bearings to prevent seizing. Remember, maintaining correct wheel alignment helps reduce stress on bearings, prolonging their life and ensuring safe towing.

- Remove the wheel and hub

- Inspect bearing materials for wear

- Clean all parts thoroughly

- Replace damaged bearings

- Check wheel alignment before reassembling

Preventive Tips to Extend the Life of Your Trailer Bearings

To extend the life of your trailer bearings, regular maintenance and proactive habits are essential. Consistently follow lubrication schedules to prevent corrosion and reduce friction. Use the appropriate bearing material suited for your trailer’s conditions, whether it’s metal or synthetic, to enhance durability. Inspect bearings frequently for signs of wear or damage and address issues promptly. Proper lubrication not only minimizes heat buildup but also extends bearing life. Remember, neglecting these steps accelerates wear and increases the risk of failure. Here’s a visual reminder:

| Bearing Material | Lubrication Schedule | Key Benefit |

|---|---|---|

| Metal | Every 5,000 miles | Long-lasting |

| Synthetic | Every 7,500 miles | Reduced friction |

| Hybrid | Every 6,000 miles | Versatile use |

Tools and Supplies You Need for Bearing Maintenance

To keep your trailer bearings in top shape, you’ll need the right tools for removal and installation. Make sure you have essential lubricants and greases on hand to protect and prolong the life of your bearings. Don’t forget safety gear like gloves and eye protection to stay safe during maintenance.

Proper Tools for Bearing Removal

Having the right tools on hand is essential for removing trailer bearings efficiently and safely. Proper tools make hub cleaning and bearing removal easier, preventing damage and ensuring smooth operation. You’ll need:

- A bearing puller or slide hammer to extract stubborn bearings

- A socket set to remove hub nuts

- A rubber mallet for gentle tap removal

- A bearing separator for precise separation

- A wire brush or scraper for hub cleaning and removing old bearing grease

Using these tools helps you avoid damaging the hub or bearing races. Once removed, clean the hub thoroughly to inspect for wear or damage, and apply fresh bearing grease during reassembly. Having quality tools guarantees you can perform maintenance confidently, reducing downtime and preventing future bearing problems.

Essential Lubricants and Greases

Choosing the right lubricants and greases is essential for keeping your trailer bearings running smoothly and extending their lifespan. Proper lubricant selection guarantees minimal friction and prevents corrosion. When selecting grease, verify grease compatibility with your bearing components to avoid chemical reactions that could cause damage. Use the following table to guide your choices:

| Lubricant Type | Best For |

|---|---|

| Lithium Grease | General trailer bearing applications |

| Synthetic Grease | High temperature, heavy load conditions |

| Marine Grease | Exposure to water or salt environments |

| Calcium Sulfonate Grease | Long-lasting, high-pressure use |

| Multi-purpose Grease | Versatile, compatible with various parts |

Always check manufacturer recommendations to ensure compatibility and peak performance. Proper lubrication prevents seizing and prolongs bearing life.

Safety Gear for Maintenance

Before starting trailer bearing maintenance, it’s crucial to equip yourself with the right safety gear to protect against potential hazards. Personal protective gear helps prevent injuries from sharp tools, debris, or hot surfaces. Follow safety protocols to ensure a safe work environment. Essential safety gear includes:

- Safety goggles to shield your eyes from debris

- Work gloves for hand protection

- Steel-toed boots to prevent foot injuries

- Ear protection if using loud tools

- Dust masks to avoid inhaling dirt or grease fumes

These items keep you safe during bearing maintenance, reducing the risk of accidents. Always inspect your safety gear before starting work and use it properly to adhere to safety protocols. Proper safety gear not only protects you but also helps maintain focus and efficiency during the maintenance process.

How to Keep Your Trailer Bearings Running Smoothly Longer

To keep your trailer bearings running smoothly longer, regular maintenance is essential. Start by checking and adjusting lubrication frequency based on your bearing material and usage conditions. Bearings made of different materials, like metal or ceramic, require specific lubrication schedules to prevent friction and wear. For metal bearings, lubricate more frequently, especially if you’re hauling in harsh environments or over rough terrain. Use high-quality grease suitable for your bearing type, and avoid over-lubricating, which can trap dirt and cause damage. Regular inspections help you spot early signs of wear or contamination. Keeping bearings properly lubricated and choosing the right lubrication schedule based on bearing material guarantees they stay in good condition longer, reducing the risk of seizing or failure during your trips.

When Should You Call a Professional for Trailer Bearing Repairs?

Knowing when to call a professional for trailer bearing repairs is essential to prevent further damage and guarantee safety. If you notice persistent noise, uneven tire wear, or excessive heat, it’s time to seek expert help. Relying on DIY fixes can sometimes lead to common mistakes that worsen the problem. You should call a professional if:

- You’re unsure how to properly inspect or replace bearings

- Bearings are severely damaged or seized

- You’ve already attempted repairs without success

- There’s visible corrosion or rust on the bearings

- The issue affects trailer stability or safety during towing

Attempting repairs without proper knowledge can cause more harm than good. When in doubt, trusting a professional ensures the job is done correctly and safely, saving you time and potential costs down the line.

Quick Tips for Troubleshooting Noisy or Seized Bearings

When you notice your trailer bearings making noise or feeling seized, quick troubleshooting can help identify the problem early. Start by inspecting the bearings for signs of insufficient bearing lubrication, such as rust or roughness. If they feel dry or gritty, re-lubricate them with high-quality grease suited for trailer bearings. If noise persists or the bearings feel extremely hot or seized, bearing replacement might be necessary. Remove the wheel and check for damage or excessive wear. Seized bearings often require immediate replacement to prevent further damage to the axle or wheel hub. Regularly inspecting your bearings and maintaining proper bearing lubrication can prevent problems, saving you time and costly repairs down the road.

Frequently Asked Questions

How Often Should Trailer Bearings Be Lubricated for Optimal Performance?

You should lubricate your trailer bearings every 12,000 miles or at least once a year, whichever comes first. Regular bearing maintenance and adhering to proper lubrication schedules help prevent seizing and damage. Always check your bearings after long trips or rough terrain, and use high-quality grease. Consistent lubrication guarantees smooth operation, reduces wear, and extends the life of your trailer bearings. Stay proactive to avoid costly repairs and downtime.

What Are the Signs of a Bearing That’s About to Seize?

If your trailer bearing is about to seize, you’ll notice some signs like unusual noises—grinding or squealing sounds—and a rough or hot hub during visual inspection. You might also see metal flakes or discoloration. Pay close attention to these clues, as they indicate the bearing is under stress and could seize soon. Addressing these signs early helps prevent costly repairs and keeps your trailer running smoothly.

Can You Repair Damaged Trailer Bearings Yourself?

Think of repairing damaged trailer bearings like fixing a leaking pipe—you can attempt DIY repair techniques, but it’s risky. While bearing replacement is doable if you’re familiar with the process, a seized or severely damaged bearing often needs professional attention. If you choose to repair it yourself, make sure you have the right tools and knowledge. Otherwise, trusting a pro ensures safety and longevity for your trailer.

How Does Weather Affect Trailer Bearing Lifespan?

Weather substantially impacts your trailer bearings’ lifespan. Temperature fluctuations cause expansion and contraction, which can loosen or damage bearings over time. Moisture exposure, especially in rainy or humid conditions, promotes rust and corrosion, reducing their effectiveness. To keep your bearings in good shape, regularly check for signs of moisture and avoid extreme temperature changes. Proper maintenance and protective measures can extend their life and prevent costly failures on the road.

What Are the Best Types of Grease for Trailer Bearings?

You should choose high-quality, lithium-based or synthetic bearing lubrication grease, as they provide excellent water resistance and durability. Always check grease compatibility with your trailer bearings to prevent issues. Proper grease guarantees smooth operation, reduces wear, and extends bearing life. Make sure to apply it thoroughly during maintenance, especially in harsh weather conditions. Using the right grease helps catch problems early and keeps your trailer running smoothly.

Conclusion

By staying vigilant and following proper maintenance, you can catch trailer bearing problems before they turn into a seized disaster. Think of your bearings as the heart of your trailer—when they’re healthy, everything runs smoothly. Regular inspections and prompt repairs keep you rolling without a hitch. Don’t wait for a warning sign; tend to your bearings like a gardener tending their plants, and your trailer will thank you with a long, trouble-free life.