Fuel-water separation is a process that removes water from your fuel before it reaches the engine, using specialized filters and settling mechanisms. Water in fuel can cause corrosion, clog injectors, and reduce engine performance over time. Keeping water out helps protect your engine’s components and maintains fuel efficiency. Understanding how these systems work and how to keep them in good shape is essential for engine health — learn more to keep your system running smoothly.

Key Takeaways

- Fuel-water separation removes water from fuel before it reaches the engine, preventing damage and ensuring optimal performance.

- Specialized filters and coalescing mechanisms cause water droplets to combine and settle, facilitating removal.

- Water in fuel can cause corrosion, clogged injectors, and engine inefficiency if not properly separated.

- Regular maintenance and testing of fuel-water separators help prevent contamination and costly repairs.

- Effective separation maintains fuel quality, protects engine components, and prolongs engine lifespan.

What Is Fuel-Water Separation and How Does It Work?

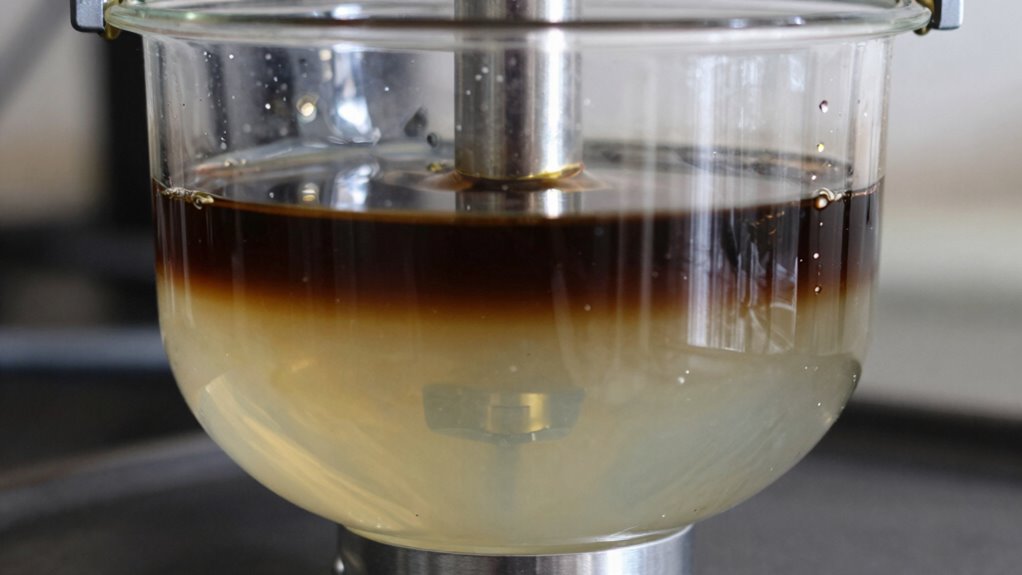

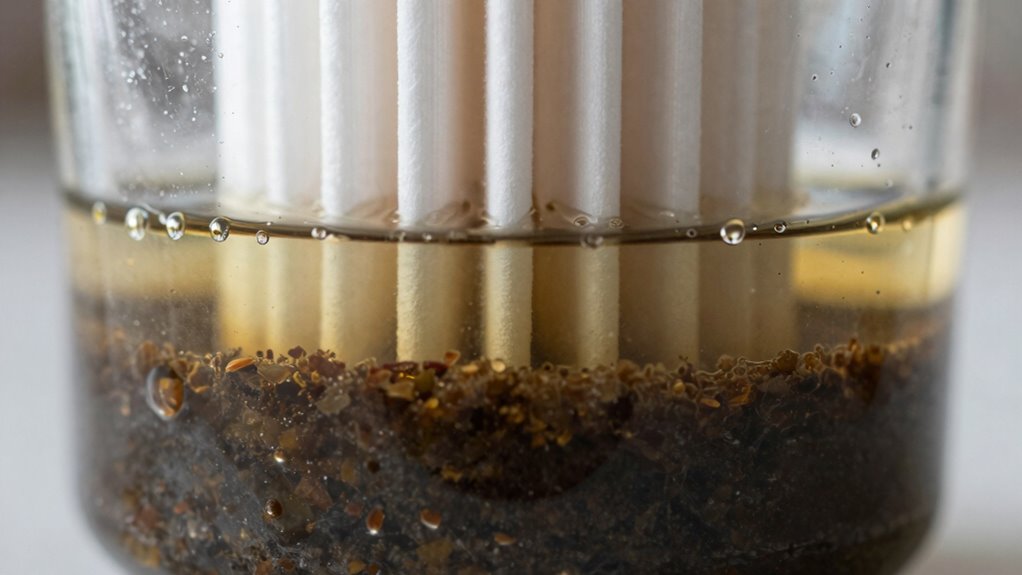

Have you ever wondered what happens when water gets mixed with fuel? Fuel-water separation is designed to remove that water before it reaches your engine. It works through fuel filtration, which captures water and other contaminants, preventing damage. When water enters the fuel system, it can emulsify, meaning it forms tiny droplets dispersed throughout the fuel. This emulsification makes water harder to detect and remove. Fuel-water separators use specialized filters that trap water particles, allowing clean fuel to pass through. Some systems also employ coalescing filters, which cause water droplets to combine and settle at the bottom for easy removal. Additionally, understanding the testing accuracy of these systems helps ensure they are functioning properly and providing reliable protection. Proper maintenance of these systems is essential to ensure their effectiveness over time, especially since water contamination can lead to corrosion and engine issues if not properly managed. Regular inspections and staying aware of fuel system health can help prevent costly repairs due to water-related damage. Moreover, choosing high-quality filters and system components can significantly improve the longevity and performance of your vehicle’s fuel system.

How Water Contaminates Fuel and Damages Your Engine

When water gets into your fuel, it can settle at the bottom and cause corrosion inside your engine. This corrosion damages critical parts and can lead to costly repairs. Additionally, water in fuel reduces efficiency, making your engine work harder and burn more fuel than necessary. To prevent these issues, it’s essential to use proper fuel storage and consider water separation devices that remove water before it reaches your engine must-see destinations and travel tips. Implementing proper fuel safety measures can significantly extend the lifespan of your engine and improve overall performance. Understanding the contrast ratio in your fuel system can also help you identify potential issues with water contamination early on, ensuring optimal fuel system maintenance. Regularly monitoring your fuel quality and employing water separation technology can further protect your engine from damage caused by water intrusion.

Water Accumulates in Fuel

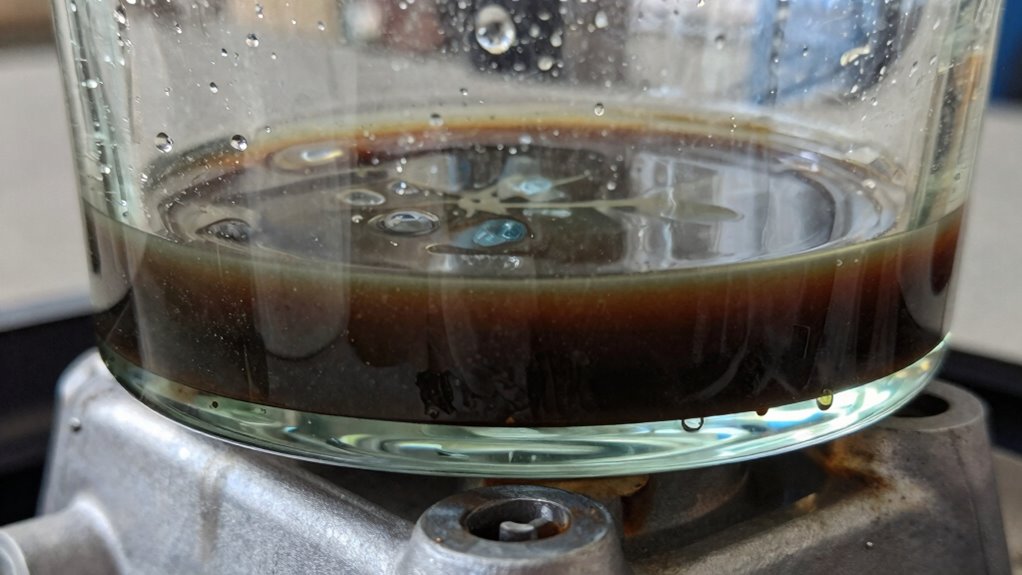

Ever wonder how water sneaks into your fuel system and causes trouble? It often happens because water can enter through contaminated fuel supplies or condensation inside tanks. Once inside, water separates from fuel because they don’t mix well. Over time, it accumulates at the bottom of your tank, creating a layer that your engine can suck in if not properly filtered. Fuel additives can help prevent water buildup by dispersing or absorbing moisture, but water filtration remains essential. Without proper filtration, water can reach your engine’s sensitive components, leading to inefficiency and potential damage. Regularly checking for water and using quality fuel with additives ensures that water doesn’t settle undetected, protecting your engine from costly issues. Understanding regional flavors and the role of additives can also help in choosing the right fuel for your vehicle’s needs. Additionally, implementing water detection methods can help identify contamination early before it causes significant harm. Proper water separation techniques are crucial for maintaining engine health and avoiding costly repairs. For optimal protection, consider using water separators designed specifically for fuel systems to enhance safety and performance.

Corrosion Causes Engine Damage

Water contamination in fuel can lead to corrosion inside your engine, causing serious damage over time. When water mixes with fuel, it creates an environment that accelerates rust and corrosion of metal components like fuel injectors, lines, and valves. To combat this, corrosion prevention methods are essential. Using fuel additive strategies can help neutralize water’s harmful effects, forming a protective barrier that inhibits rust formation. Regularly adding specialized additives keeps water dispersed and prevents it from settling and causing localized corrosion. Maintaining clean fuel systems not only extends engine life but also guarantees peak performance. By proactively managing water contamination through proper corrosion prevention and fuel additive strategies, you safeguard your engine from costly damage and keep it running smoothly for longer.

Reduced Fuel Efficiency

Contaminated fuel with water reduces your engine’s efficiency by disrupting the combustion process. When water ingress occurs in your fuel system, it causes fuel contamination, leading to uneven burning and poor engine performance. Water doesn’t combust like fuel, so it creates incomplete combustion and reduces the power output. This inefficiency means your engine works harder, burning more fuel to produce the same power, which lowers your fuel economy. Additionally, water in fuel can cause clogging of filters and injectors, further impairing performance. Over time, these issues force you to refuel more often and increase operating costs. Proper fuel-water separation prevents water ingress, ensuring your fuel remains clean and your engine operates at peak efficiency. Implementing effective fuel-water separation systems can significantly extend the lifespan of your engine components. Regular fuel system maintenance is crucial for early detection and prevention of water contamination, helping to avoid costly repairs. Investing in reliable fuel filters can also help catch water before it reaches sensitive engine parts. Maintaining a clean fuel system and monitoring for water presence is essential for preventing engine damage.

Signs Your Fuel Has Water and Needs Separation

If your fuel starts to show signs of water contamination, you’ll notice certain telltale symptoms that indicate the need for separation. Fuel contamination with water often leads to inconsistent engine performance, such as rough idling or misfires. You might also see water detection signs like water droplets or sediment in your fuel filter or at the bottom of your fuel tank. Another indicator is fuel separation—when water separates from fuel and settles at the bottom, making it obvious that water has infiltrated your system. Understanding how to perform fuel-water separation can help you address contamination more effectively. If you notice these signs, it’s a clear signal that your fuel needs separation. Addressing water contamination promptly helps prevent engine damage and keeps your fuel system operating smoothly. Additionally, understanding the fuel-water separation process can improve your ability to manage contamination issues effectively. Familiarity with fuel system maintenance techniques can help you detect and prevent water buildup before it causes serious problems. Recognizing the signs of water in fuel early can save you time and money on repairs.

How Fuel-Water Separators Keep Your Fuel Clean and Water-Free

Fuel-water separators actively remove water and contaminants from your fuel before they reach your engine, guaranteeing your system runs smoothly. They achieve this through effective fuel filtration, trapping dirt, debris, and water particles. Inside the separator, water detection mechanisms identify the presence of water, triggering alerts or automatic drainage to prevent water buildup. The separation process relies on gravity and coalescing filters that encourage water droplets to merge and settle at the bottom, where they can be drained easily. This keeps your fuel clean and water-free, reducing the risk of corrosion, clogged injectors, and poor engine performance. Regularly maintaining your fuel-water separator ensures it continues to perform at its best, providing your engine with the clean, water-free fuel it needs to operate reliably. Incorporating digital monitoring systems can help track separator performance in real-time, ensuring optimal fuel quality at all times.

Tips for Maintaining Effective Fuel-Water Separation Systems

To keep your fuel-water separation system working effectively, you need to perform regular inspections to catch issues early. Using quality separation equipment guarantees reliable performance and reduces maintenance costs. Staying on top of these practices helps maintain clean fuel and prevents costly engine problems.

Regular System Inspections

How often should you inspect your fuel-water separation system to make certain it works effectively? Regular inspections are essential for maintaining a healthy fuel system. You should check the water separator at least every 50 to 100 hours of engine operation or monthly, whichever comes first. During inspections, look for signs of water accumulation and sediment buildup. If you notice water, drain it immediately to prevent corrosion and engine damage. Also, verify that your fuel additives are functioning properly, as they can help prevent water from settling. Keeping your system clean and well-maintained ensures ideal fuel flow and reduces the risk of water-contaminated fuel reaching your engine. Routine inspections save you money and extend your engine’s lifespan by catching issues early.

Use Quality Separation Equipment

Using high-quality separation equipment is essential for guaranteeing your fuel-water separation system works effectively. Quality units improve water absorption, preventing water from reaching your engine. When selecting equipment, prioritize those designed for ideal fuel blending and water removal. Reliable separation systems can handle varying fuel qualities and help reduce sediment buildup, ensuring consistent performance. Regularly check that filters and separators are functioning properly, and replace parts as needed to maintain efficiency. Using inferior equipment can lead to water bypass and fuel contamination, risking engine damage. Invest in proven, durable separation technology to enhance water absorption and keep your fuel clean. Proper maintenance and quality equipment together ensure your system operates at peak efficiency, protecting your engine and extending its lifespan.

How to Choose the Best Fuel-Water Separator for Your Vehicle

Choosing the right fuel-water separator begins with understanding your vehicle’s specific needs and operating conditions. Consider how often you refuel, the quality of your fuel source, and your typical driving environment. Look for a separator that integrates advanced filtration technology to effectively remove water and contaminants. Some units are compatible with fuel additives that enhance separation efficiency, especially in challenging conditions. Check the flow rate to ensure it matches your engine’s requirements, and consider ease of maintenance to keep your system functioning adequately. Reading product reviews and consulting your vehicle’s manufacturer recommendations can help guide your choice. Ultimately, selecting a separator designed for your specific use helps protect your engine and extends its lifespan.

Troubleshooting Water in Fuel Problems and When to Seek Help

Water in fuel can cause serious engine problems, especially if left unaddressed. If you notice rough running, reduced power, or engine misfires, water ingress might be the culprit. To troubleshoot, check for signs like sediment or cloudy fuel. Use a water-finding paste or test strips to detect contamination. If water is present, drain the fuel system immediately and inspect your fuel source for leaks or contamination points. Consider these common scenarios:

| Cause of Water Contamination | Symptoms to Watch For | Recommended Action |

|---|---|---|

| Fuel storage issues | Rusty fuel, sediment | Drain and replace fuel |

| Water ingress during refueling | Engine hesitation | Inspect caps and seals |

| Poor fuel quality | Engine stalls | Use treated fuel or filters |

| Condensation inside tank | Milky fuel | Regularly drain water |

Seek professional help if problems persist to prevent engine damage.

Frequently Asked Questions

Can Fuel-Water Separation Systems Prevent All Engine Water Damage?

Fuel-water separation systems can substantially reduce engine water damage, but they can’t prevent it entirely. While they help stop water from causing engine corrosion and improve fuel efficiency, some water might still slip through, especially if the system isn’t maintained properly. To protect your engine, combine these systems with regular inspections and proper fuel storage, ensuring peak performance and longevity.

How Often Should I Service My Fuel-Water Separator?

Think of your fuel-water separator as a health check-up for your engine. You should perform maintenance at regular service intervals, usually every 100 hours of operation or as recommended by your manufacturer. Regularly inspecting and servicing your separator prevents water buildup, keeps fuel clean, and ensures smooth engine performance. Don’t wait for problems—stay proactive with your maintenance frequency to avoid costly repairs and keep your engine running strong.

Are Fuel-Water Separators Necessary for Diesel and Gasoline Engines?

Yes, fuel-water separators are necessary for both diesel and gasoline engines. They prevent fuel contamination caused by water accumulation, which can lead to engine issues like corrosion or poor performance. By removing water from your fuel, separators help guarantee your engine runs smoothly and efficiently. Regular maintenance and timely replacement of the separator are vital to keep water and contaminants out of your fuel system, protecting your engine over time.

What Are the Environmental Impacts of Improper Water Disposal?

Did you know improper water disposal can cause serious environmental harm? When you discard water contaminated with oil or fuel, it leads to water pollution, harming aquatic life and ecosystems. Oil contamination from improper disposal pollutes groundwater and surface water, risking human health. Always dispose of water responsibly, using proper facilities, to prevent environmental damage and reduce your ecological footprint. Your actions directly impact the health of our planet.

Can You Use Aftermarket Fuel-Water Separators on Any Vehicle?

You can generally use aftermarket fuel-water separators on many vehicles, but you should verify their aftermarket compatibility first. Make sure the separator fits your fuel system and meets your engine’s needs. Follow the installation guidelines closely to ensure proper function and avoid damage. If unsure, consult your vehicle’s manual or a professional to verify that the aftermarket separator is suitable for your specific make and model.

Conclusion

Think of fuel-water separation as a crucial shield protecting your engine, much like a moat guards a castle. When you keep water out of your fuel, your engine runs smoothly and lasts longer. Regular maintenance and choosing the right separator are your best defenses. Stay vigilant, and don’t let water sneak in like an unwelcome guest. With proper care, your engine will perform reliably, just like a well-oiled machine ready to conquer the road.